Freezing for freshness, cooling against spoilage

Of course, we all want our vegetables to be full of vitamins and our apples to be tasty and crisp. And one factor is often the key here: refrigeration. Proper cooling inhibits the proliferation of microorganisms, and freezing permanently seals freshness in these foods. The success of frozen berries, pizzas, French fries, and many other foods is also based on the expertise of our refrigeration specialists.

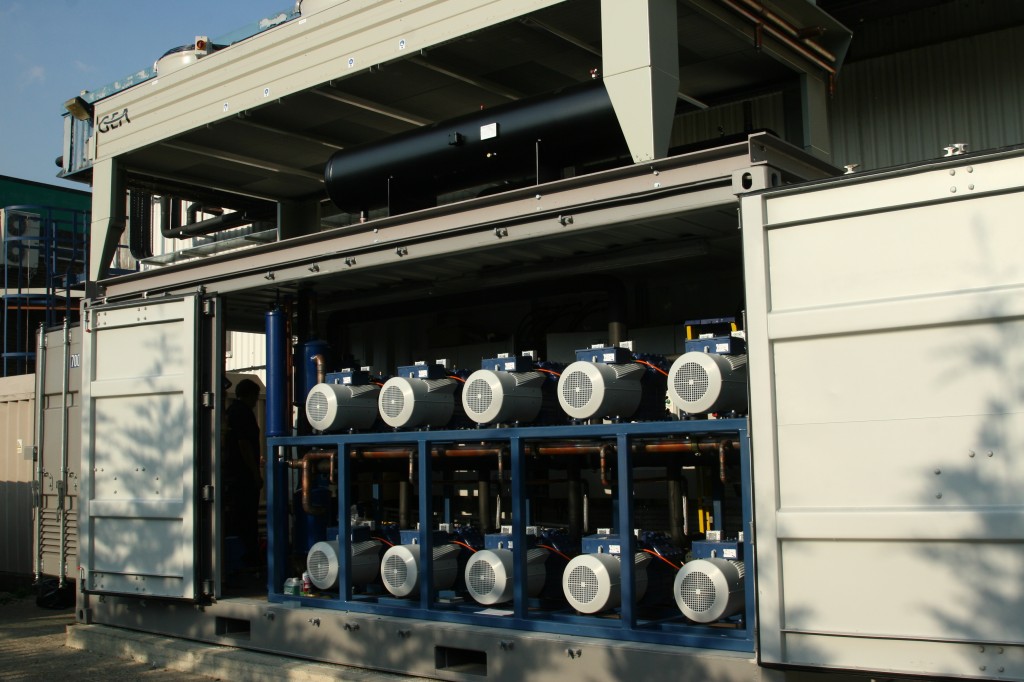

Bock for Efficiency in Cold Storage

Southern Sales & Services supply Bock compressors in operation all over the world ensuring effective cold storage. This has a crucial effect on the quality and the keeping quality of your merchandise – and on your good reputation.

We offer product selection designed around your individual particular application requirements. Our advanced technical team can assist you with the bespoke design process and fabrication using optimal solutions for your new compressor pack . If you are planning on upgrading your cold-storage facilities then please do not hesitate to contact us regarding the case study of your original inefficient refrigeration system.

Older technology to chill/freeze cold stores is found to be inadequate and are now being replaced with brand new bespoke design systems using Bock air-cooled HA compressors. The government funded ECA – Enhanced Capital Allowance scheme is now used to further reduce your carbon footprint and save on your business Energy bills. Invest the initial capital and then claim 100% of the products and installation costs using the Bock range of air-cooled compressors, which qualify as one of the listed energy saving products required to benefit from the scheme.

Bock for Efficient solutions for Distribution Centres

Southern Sales & Services are a well-versed team when it comes to storage and transport of the newest innovations from the convenience food sector. The trend to prepared and ready-to-eat products is reflected by appreciably greater refrigeration needs and, not least, by great changes in the appearances of supermarkets. It is especially the larger food retailers who are returning to their roots and are banning many non-food articles from their shelves.

They increasingly offer their customer a larger selection of fresh, prepared, and ready-to-eat products: for example, salad mix for the office lunch break. This product group requires additional energy for logistics, stores, and presentation. In addition, the trend to longer opening hours is also associated with greater energy consumption. What could therefore be more logical than to strike a good balance between quality and costs with an investment in an advanced, energy-efficient refrigeration system?

Every single area of the industrial branch of food cold stores and distribution poses its specific requirements for effective temperature control.

Solutions for Mobile Chilled Vending

Southern Sales & Services offer a wide range of solutions for ice cream vans and other vendors in the mobile Chilled Vending Industry.

There are a variation of compressor models you can choose from to meet your application. The most popular are the Bock FK2 (Blue) and the all new Bock FK20 range (Silver). As an alternative we also offer the York ER210R compressor and the Valeo/Seltec TM series range of compressors.

We offer a full range of spares and accessories as well as units for quick and easy maintenance or replacement.

© 2023 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.