Southern Sales & Services provide can turnkey packages for all aspects of refrigeration and air conditioning systems used within the marine and maritime industries. Our systems offer numerous solutions for meeting state-of-the-art refrigeration technology requirements.

We recommend BOCK compressors, which are available in a diverse range of models and sizes, with the latest compressor electronic control technology. BOCK have pioneered the development of technical solutions which set the benchmark for energy and efficiency, operating safety and reliability, not only for compressors but for the whole refrigeration plant.

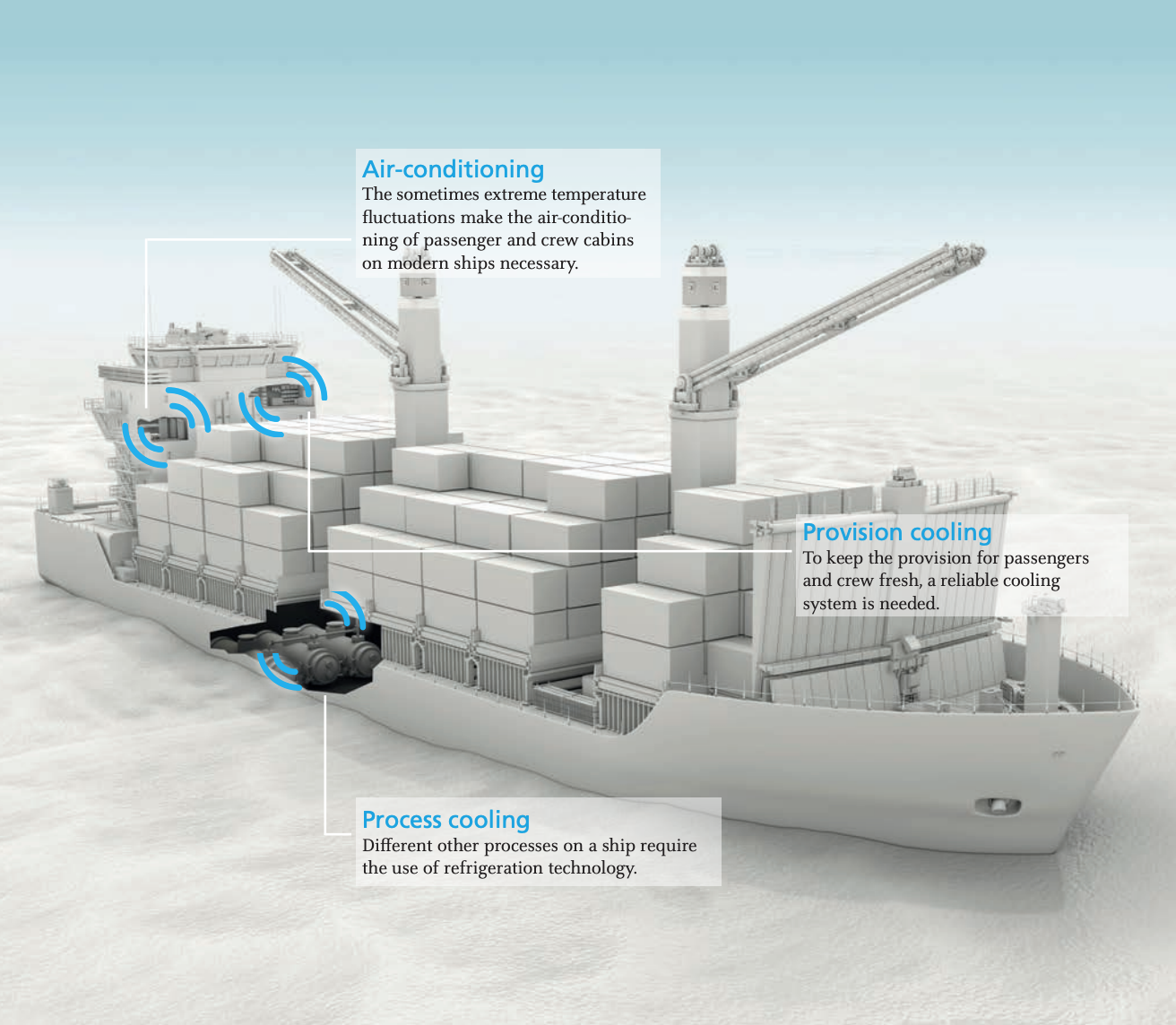

We can provide solutions for treating fuel, oil, lube oil, bilge water and ballast water, whilst our air conditioning, refrigeration and freezing technology ensures that passengers are comfortable and that cargo arrives in good condition.

All our equipment and cooling technology are precisely tailored to the requirements of a wide variety of vessels. We divide our market into the following applications:

Maritime Applications

Container Shipping

Fishing Industry

Ice Machines

BOCK Maritime Cruise and Passenger Solutions

For holiday-makers who book a cruise, the ship experience itself has increasingly become the actual destination. Cruise ships are becoming ever larger, and passengers expect an extensive offering of entertainment, sports, wellness and luxury.

All of this of course includes a comfortable room climate – already enough of a challenge in normal hotels. On cruise ships, though, it represents truly difficult terrain: which BOCK gladly moves through for you. We have, for example, equipped passenger ships of Carnival Cruise Lines Inc. and of P&O Cruises with HVAC systems that create comfy coolness during hot nights on board.

The general trend for wellness and good health has also extensively entered the world of cruise cuisine. In fact, cruise passengers expect delicious but healthy food on board. The cooks of the countless restaurants on board cruise ships therefore expect that their fresh ingredients are stored under perfect conditions. In order to ensure sophisticated cooling in storage rooms for foods and beverages, BOCK refrigeration systems are hard at work for the two reference cruise lines mentioned above. Those in charge of such restaurants take it absolutely for granted that the quality and reliability of such systems are flawless.

Cooling and refrigeration for passenger ships:

- Chillers for comfort climate control

- Refrigeration technology for storage of food and beverages

- Heat exchangers

- Air-handling units

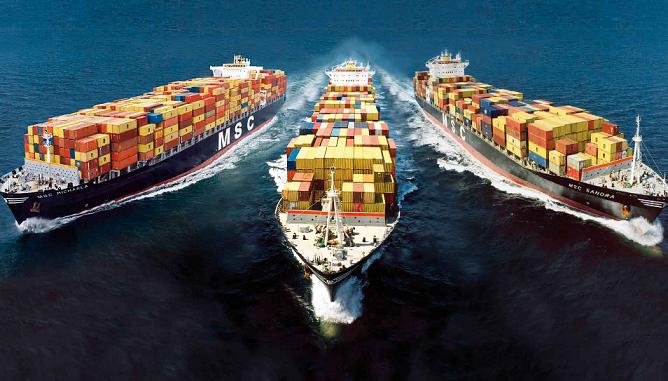

BOCK Marine Container Shipping Solutions

To ensure cargo arrives in the best possible condition, BOCK’s new refrigeration technology is specially designed for reefer vessels to save costs and work on an improved carbon footprint. BOCK’s revolutionary air distribution system no longer requires traditional and expensive grating floors. By placing special coolers on one side of the cargo, cooled air is now better circulated through the cargo improving the preservability of goods and using less energy in the cooling process.

The advantages of this system:

- CFD files indicate that cooled air is circulated even better through the cargo vs. conventional grated floors, improving the preservability of goods

- No investment in heavy grated floors is required

- No replacement or repair is needed to damaged, existing grated floors

- By eliminating grated floors, the ship weighs less, resulting in lower fuel consumption

Focus on Sustainability

Are you searching for sustainable solutions? BOCK addresses the high demand for carbon-footprint-reducing solutions by helping customers phase out synthetic refrigerants and replace them with natural ones, like NH3 as a primary refrigerant and CaCl2 as a secondary option.

Using NH3/CaCl2 for cooling purposes has two clear advantages: due to an optimised configuration with NH3/CaCl2, freezing temperatures can be lowered. This way, your power consumption is reduced and at the same time you reduce your carbon footprint. In addition, we offer heat recovery solutions that further lower energy consumption and help the environment.

Geneglace Ice Systems for Fishing

To ensure a long life for business relationships as well, Geneglace offers effective cooling or freezing technology for every fisherman. The daily routine of fishing work varies considerably. Some fishing boats leave port in early morning and return to harbor on the same day. Others are underway for days on end. To maintain freshness quality in any case, the catch should be immediately cooled to around 0 °C. There are two solutions possible here: the ice is either loaded on board when the ship leaves the harbor, or the ice is produced on the ship as needed.

This all sounds easy enough, but it demands considerable expertise. Ice machines dedicated to this purpose cool water in a vertical cylinder until it freezes on the inner wall. The ice is scraped off and falls into an ice container located below. The flake ice gained in this way is ideal for use on the high seas, especially since it is “fish-friendly”. Despite the name “flake ice”, the small curved pieces of ice have no sharp corners – which protect the thin, delicate skin of a fish. Flake ice is particularly gentler on fish skin when it has been made from seawater: the salt content makes the ice even “softer”. In addition, this ice is dry, and the fish does not swell. The cool mass has just the right consistency – not too hard and not too liquid – and can be easily handled on a ship, since it can be heaped up. Cold: yes. Too cold: no. There is a temperature below which fish cannot be stored. Otherwise, dreaded freezer burn will take place and will rob seafood of its taste and its attractive colour.

The purpose of the ice, however, is not only to keep the fish at a particular temperature. As the ice slowly melts, this automatically washes the fish – and the natural mucous layer and the moisture of the skin will remain. Whether for fresh water or sea water – Geneglace knows what it’s all about. Their 40 models of Geneglace ice machines offer the perfect solution for virtually any application. Daily ice capacity of these machines is between 200 kg and 50 metric tons, depending on the equipment type. Ice machines that directly produce the ice on board are equipped with ice generators especially designed for the rough conditions that prevail on the high seas. They chug along even despite heavy waves and are not sensitive to corrosion by the saline content of sea air. These ice generators are available alone or as compact ice machines with ice packs. Likewise available are accessories such as the following: ice towers for storage, conveyor belts, insulated transport boxes, and dosing systems.

- Substantial cooling power

- Dry (no water) and sub-cooled at – 5 °C

- Latent heat 100 % available

- Excellent cooling capacity

- Large heat exchange surface area

- Maximal thermal exchange

- Precise temperature control

- 100 % of ice and precise calculation

- Ease of handling/storage

- Free flowing

- Does not stick together

© 2025 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.