BOCK Joins the Danfoss Family

Earlier this year, BOCK entered a new chapter in its long history as it joined the Danfoss family.

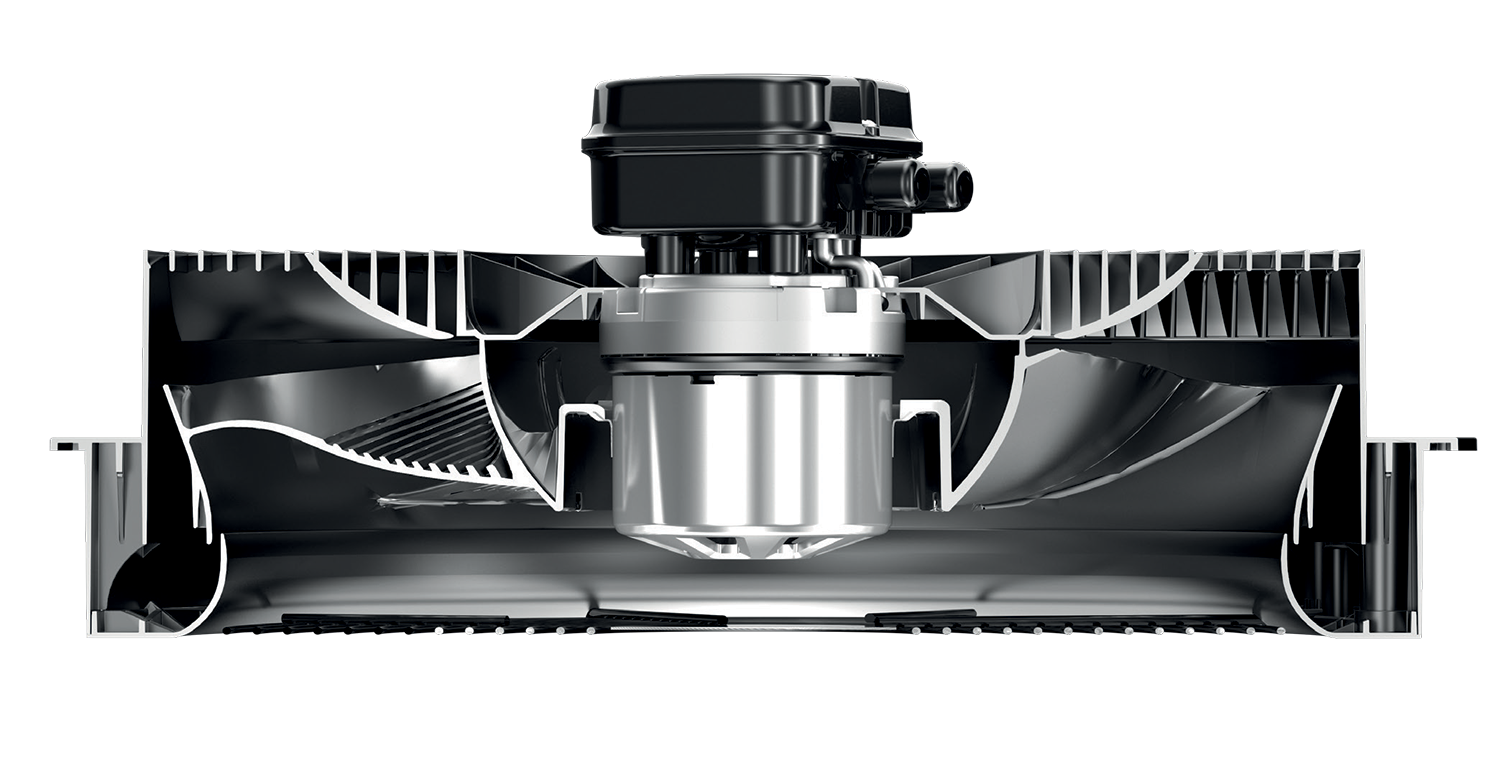

BOCK’s best-in-class technology is a natural fit for Danfoss’ extensive existing cooling and heating portfolio, and unifying these two brands will help them both accelerate their energy efficiency and decarbonization efforts.

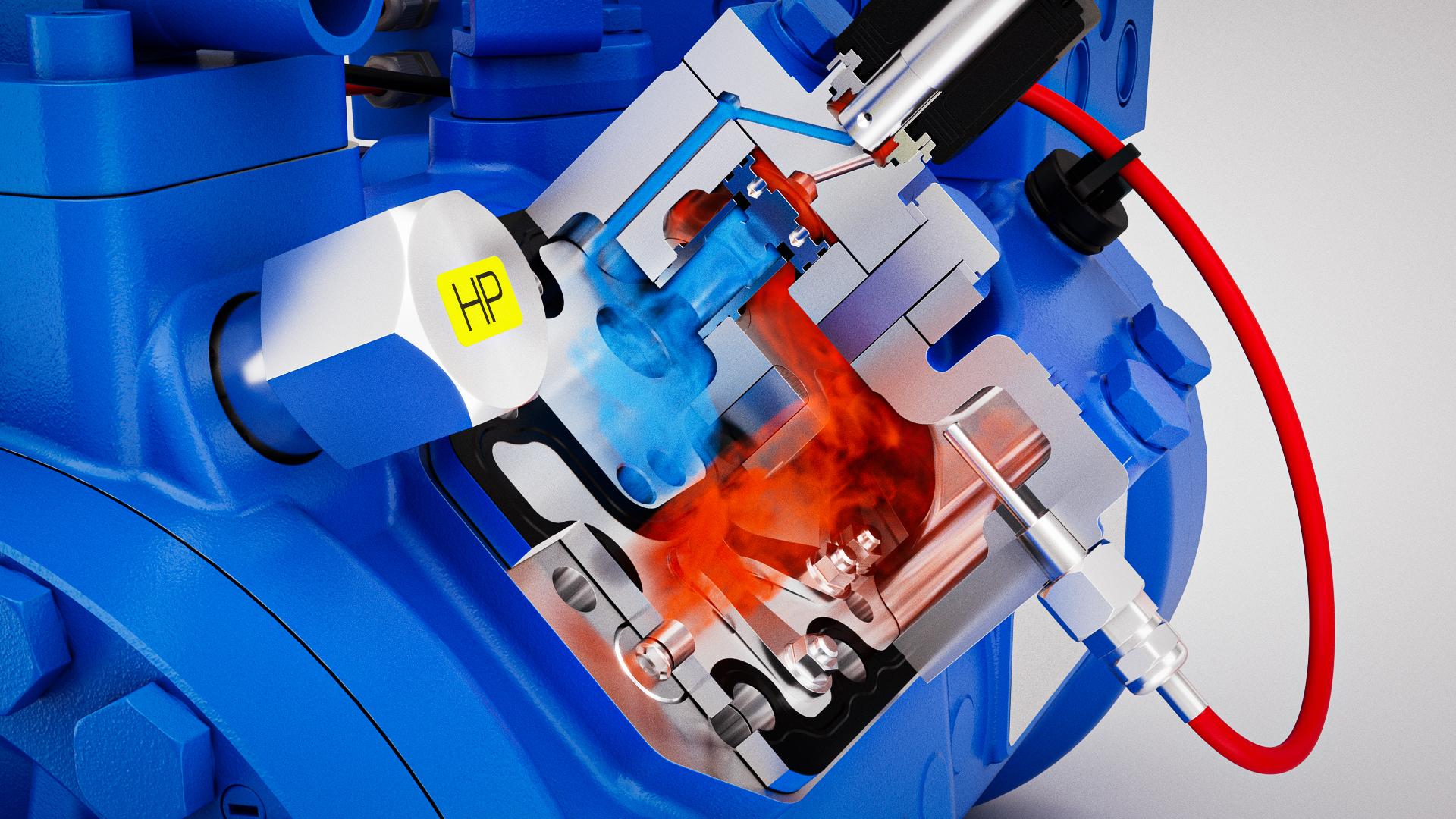

As part of the Danfoss Commercial Compressors division, BOCK will become a distinct product brand name for semi-hermetic reciprocating compressors. BOCK’s renowned CO₂ and low-GWP (Global Warming Potential) semi-hermetic reciprocating compressors and condensing units will compound Danfoss’ position as a full-service provider for greener cooling and heating solutions.

You can read more about the acquisition on Bock’s website here, and Danfoss’s site here.