We are able to develop a leading edge strategy for your process control or SCADA application. Data management, system monitoring, system control over TCP/IP (over the Internet) is standard with all of our solutions. Now you can override, change control parameters, analogue settings on your application from anywhere in the world using just an Internet browser connected to the WWW. The system can be configured to send an email to a system manager, or technician in the event of a system alarm being raised. Real time monitoring and remote control from any standard PC anywhere on the planet.

Data can be collated from a number of sources, including: thermocouples, pressure transducers, energy meters, flow sensors, liquid level-sensors and more. The connection can be either hard wired, or sent over ZigBeeTM wireless network, or networked over TCP/IP. We write custom software to control your application, we can then assign various parameters to be available remotely to any user who is authorised to log into the system. Data can then be monitored and controlled in real time over TCP/IP via the Internet using a standard web browser.

The control strategy will be optimised to save energy and this will be reflected in reduced energy bills and lower C02 emissions. The system can be used in conjunction with other energy efficient products, to develop a system that may meet the criteria for the UK Gonvernments Energy Capital Allowance scheme (ECA). Here a company may offset the installation costs of certain ECA eligible energy efficient products and systems against their corporate tax bill.

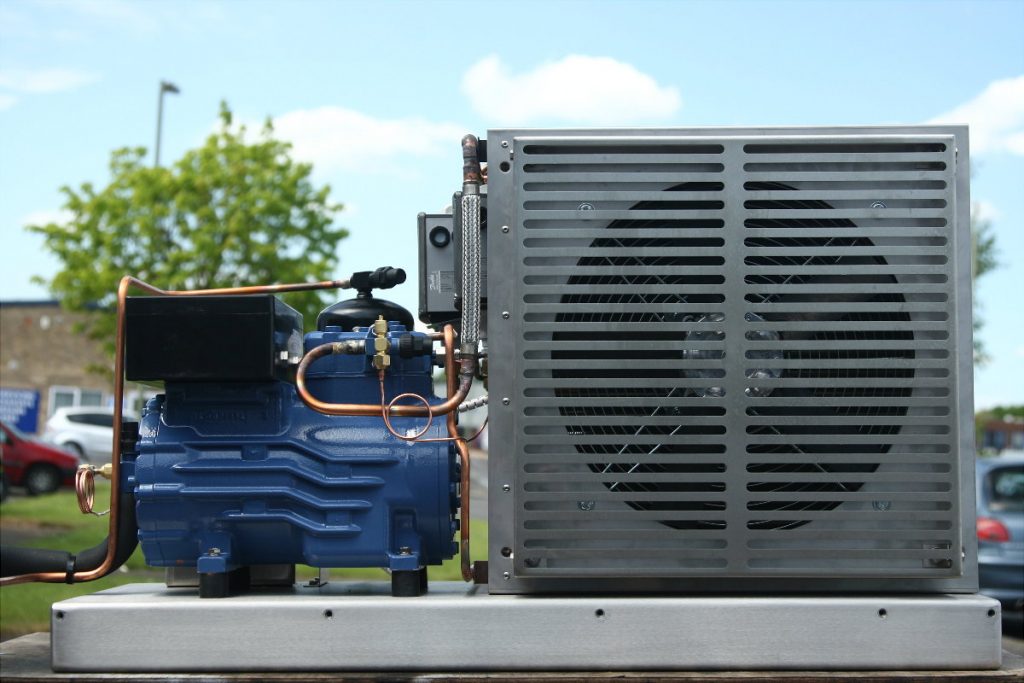

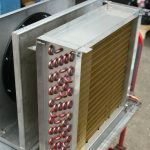

(SCADA) remote system control & data acquisition is the future of cutting-edge refrigeration system design.