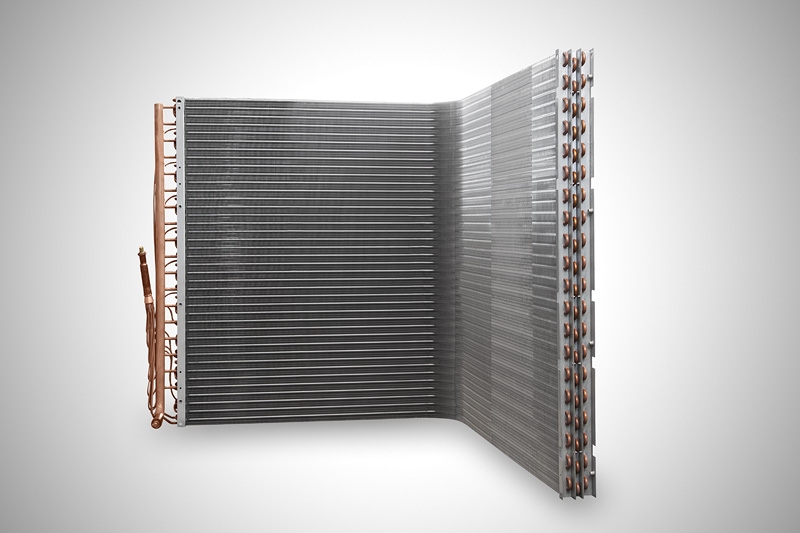

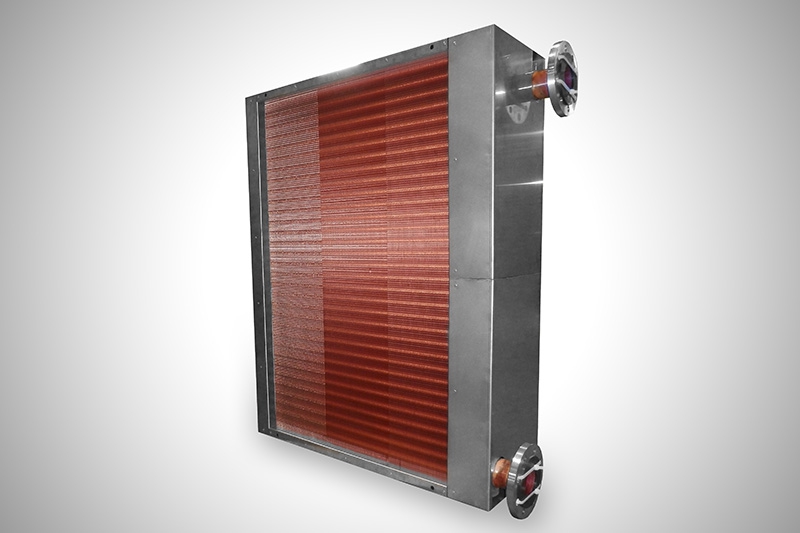

Southern Sales & Services offer a superbly constructed range of bespoke condensers and evaporators manufactured in a number of different materials. The coils are available for a huge variety of cooling applications throughout a wide range of Industries seen listed using the drop down at the top of the page.

The bespoke program is designed for all your coil solutions. If you have a project and request the latest technology in coil design and manufacture, then please contact our technical team who will assist you and can arrange an on-site visit if required.

For more information then please do not hesitate to contact us by phone or by using the quick contact for at the bottom of the page.

4 COILS TECH

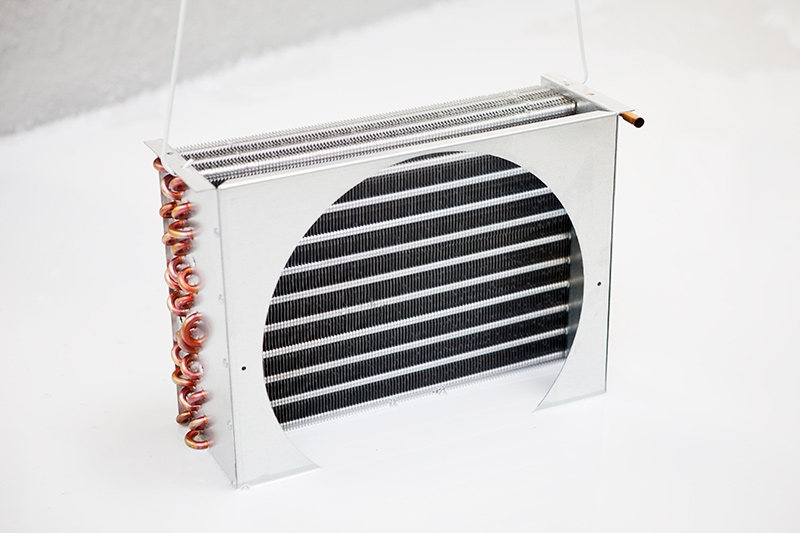

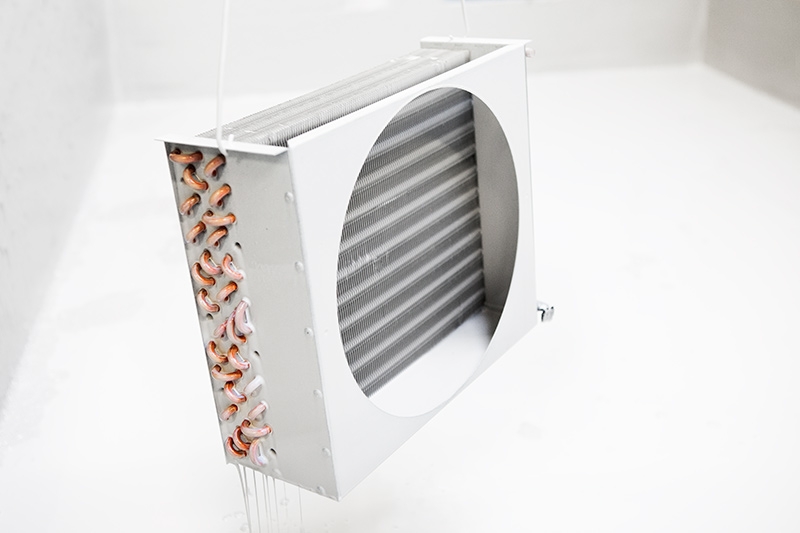

Southern Sales and Services are UK distributors for 4 COILS TECH (formerly known as LEEL COILS EUROPE). They produce conventional finned pack heat exchangers – coils for OEM and other customers, manufactured from the highest quality copper tubes and aluminium or copper fins. Critical components for the coils, such as the headers and connecting pipes, are manufactured in house. Specially evaluated quality suppliers and sub-contractors are used for the outsourced components.

4 COILS TECH can supply coils with different surface finishing, such as powder coating or LCE Coating corrosion protection, as well as manufacturing coils with alternative pre-coated aluminium fins or tinned copper fins.

Coil Options

- Condenser Coils

- Evaporator Coils

- Reversible Coils

- Water & Glycol Coils

- Industrial Coils

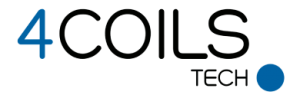

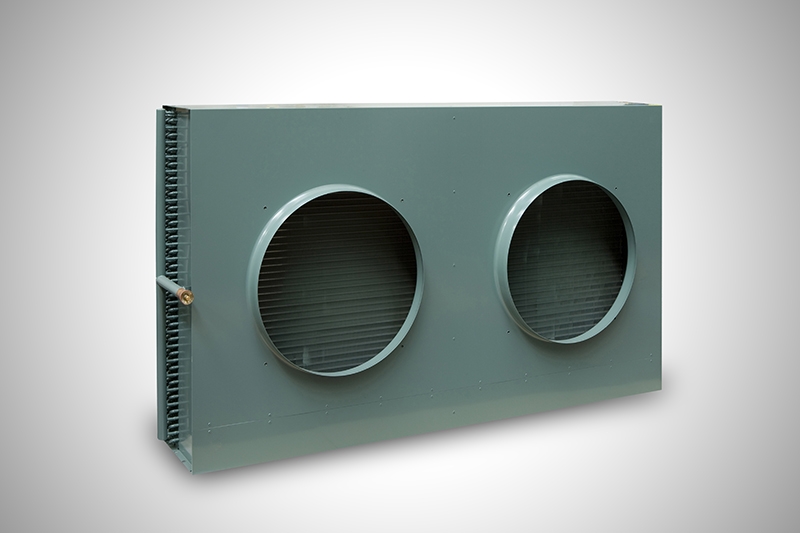

CONDENSER COILS FOR HVAC&R

Application

- Remote condensers

- Condensing units

- Close control AC

- Showcases

- Display cases

- Bottle coolers

- Milk tanks

- Transportation AC and refrigeration

Offered Solution

- Straight or formed, L or U or O-shaped coils Integrated fan shrouds for axial fans of 250 mm up to 630 mm in diameter

- High-quality powder paint in 12 standard colours

- LCE Coating anti corrosion and antimicrobial protection

- Pre-coated epoxy (gold) or blue (hydrophilic) fin material is available

- Smooth tube, inner grooved tube or super-grooved tube for condensing application

- Circuiting for horizontal, vertical or combined use

- Circuiting with tripods and with sub-cooling sections available

- An optimum solution of the system condenser coil – fan can be achieved through our selection program (OemBat).

Technical Specification

TUBES

- Copper

- 7 mm, 5/16“, 3/8“, 12 mm, 1/2“, 5/8“

- Smooth, Smooth thick-walled, Grooved, Supergrooved (deeper grooves)

- Connection to several circuits available

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan (16 possible diameters)

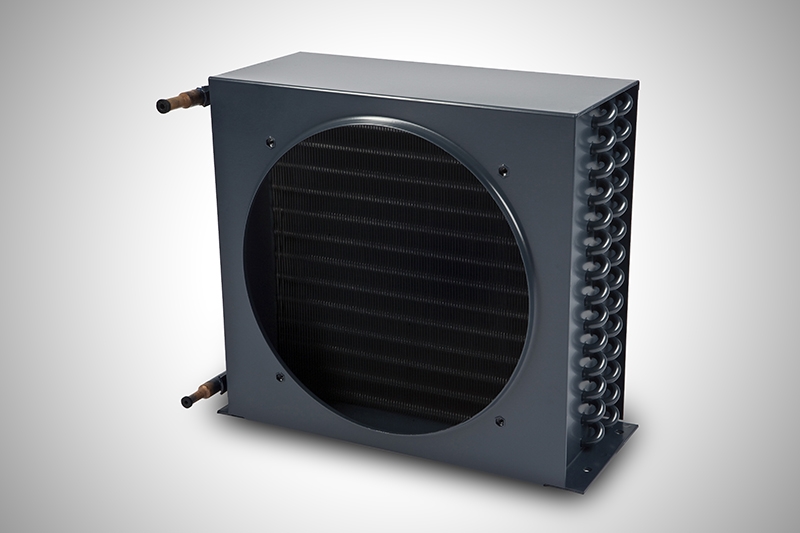

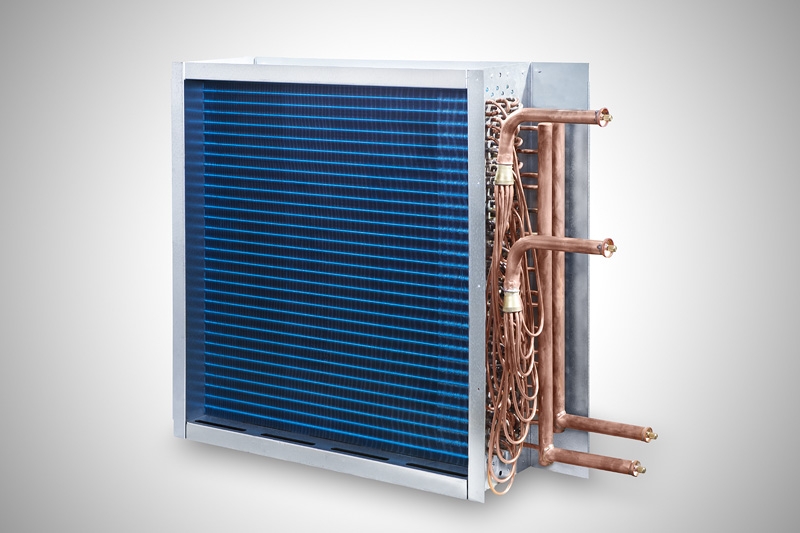

EVAPORATOR COILS FOR HVAC&R

Application

- Close control AC

- Rooftops

- Air-handling units

- Fan-coils

- Ducted systems

- Air curtains and transportation AC

- Bottle coolers

- Chillers

- etc.

Offered Solution

- Straight or formed, L or U or O-shaped coils

- Smooth or inner grooved tube with different diameters and thickness of wall

- Different approach of plain, corrugated or louvered fin profiles

- LCE Coating anti corrosion and antimicrobial protection

- High-quality powder paint

- Pre-coated epoxy (gold) or blue (hydrophilic) fin material is available

- Maximum of 10 mm fin spacing

- Defrosting slots are available in certain cases

- An optimum solution of the system of evaporator coil-fan can be achieved through our selection program (OemBat), including the design of the refrigerant distributor

Technical Specification

TUBES

- Copper

- 7 mm, 5/16“, 3/8“, 12 mm, 1/2“, 5/8“

- Smooth, Smooth thick-walled, Grooved, Supergrooved (deeper grooves)

- Connection to several circuits available

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan

CAPILLARIES

- 5/32”, 3/16”, 1/4”, 5/16”

DISTRIBUTORS

- Standard (nozzle type)

- Venturi

- Special hot gas distributor (with connection ASC for hot gas)

REVERSIBLE COILS

Application

- Heat pumps

- Air conditioning

- Dehumidifiers

- etc.

Offered Solution

- Design is adapted to the planned application

- For heat pumps – the design resistant to vibrations, special connections or circuits for hot gas or tubes for resistance heaters

- For dehumudifiers – evaporator and condenser coil in the same casing

- LCE Coating anti corrosion and antimicrobial protection

- High-quality powder paint

- Pre-coated epoxy (gold) or blue (hydrophilic) fin material is available

- An optimum solution of the system of evaporator coil-fan can be achieved through our selection program (OemBat), including the design of the refrigerant distributor

Technical Specification

TUBES

- Copper

- 7 mm, 5/16“, 3/8“, 12 mm, 1/2“, 5/8“

- Smooth, Smooth thick-walled, Grooved, Supergrooved (deeper grooves)

- Connection to several circuits available

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan

CAPILLARIES

- 5/32”, 3/16”, 1/4”, 5/16”

DISTRIBUTORS

- Standard (nozzle type)

- Venturi

- Special hot gas distributor (with connection ASC for hot gas)

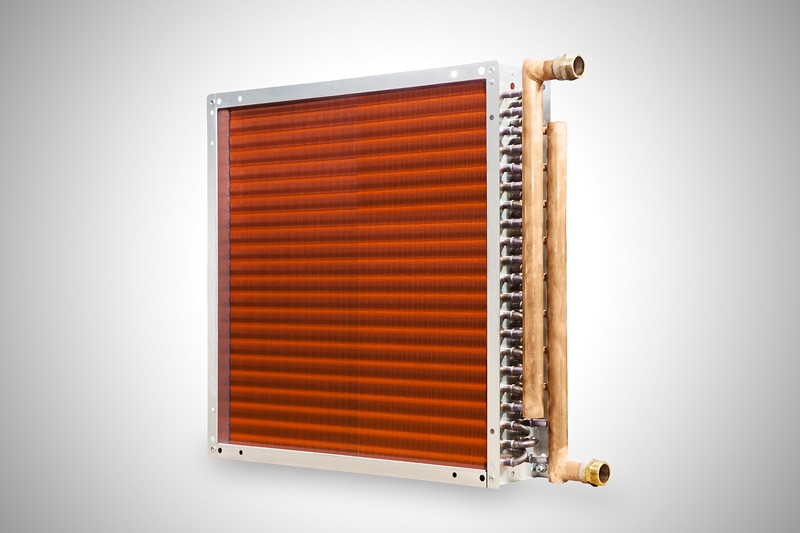

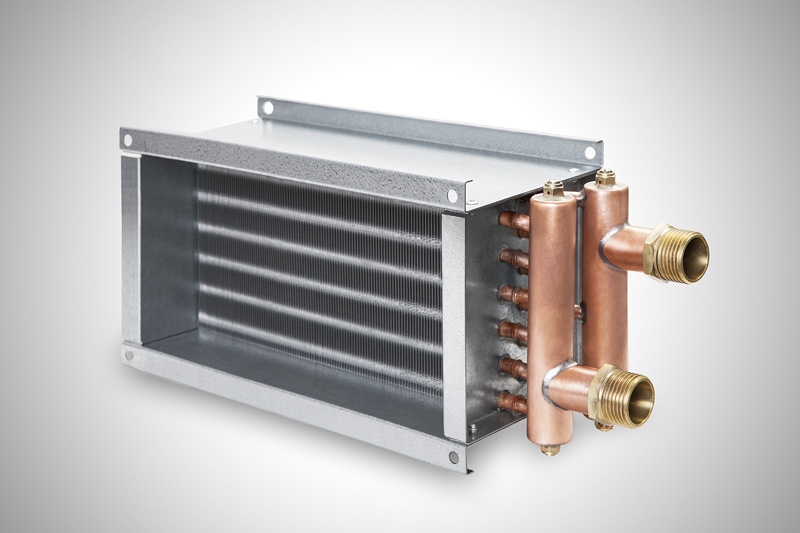

WATER AND GLYCOL COILS

Application

- Unit heaters

- Fan coils

- Convectors

- Air handling units

- Ducted systems

- Air curtains

- Cold beams

- Chillers

- Glycol heat recuperation circuits

- etc.

Offered Solution

- A wide variety of tube diameters from 7 up to 16 mm

- Vertical, horizontal or inclined positions of the connection

- Coils with horizontal or vertical tubes

- The standard circuiting ensures correct drain and purge

- Our selection program (OemBat) allows the customer to design the correct circuiting and select the right connection size

- The correct circuiting and selection the optimum connection size

Technical Specification

TUBES

- Copper

- 7 mm, 5/16“, 3/8“, 12 mm, 1/2“, 5/8“

- Smooth, Smooth thick-walled

- Connection to several circuits available

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

END FITTINGS

- A wide range of end fittings (male/female)

- Brass or steel design

- Union nut

- Flanges

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan

- Diffusers for involvement in pipeline

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

INDUSTRIAL COILS

Application

- Oil coolers for hydraulic systems

- Water and liquid coolers for industry and power plants

- etc.

Technical Specification

TUBES

- Copper

- 7 mm, 5/16“, 3/8“, 12 mm, 1/2“, 5/8“

- Smooth, Smooth thick-walled, Grooved, Supergrooved (deeper grooves)

- Connection to several circuits available

- Up to 15 m long fin surface

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan

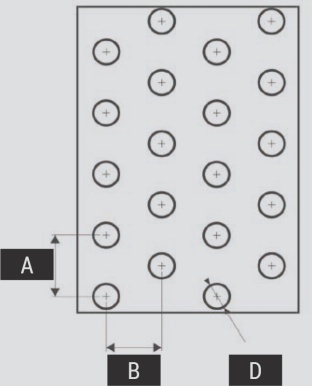

Production Capabilities

LEEL Coils production capabilities are summarised in the following overviews:

| Pattern | D | A | B | Corrugations | Europe |

|---|---|---|---|---|---|

| 0S1 | 5.00 | 20.00 | 17.32 | G, P, E | |

| 1S1 | 7.00 | 25.00 | 12.50 | G, P | |

| 2S1 | 7.94 | 25.40 | 19.05 | G*, R, P | |

| 2S9 | 7.94 | 25.40 | 19.05 | E | |

| 3S2 | 9.52 | 25.40 | 19.05 | G, P | |

| 3S9 | 9.52 | 25.40 | 19.05 | E | |

| 3S3 | 9.52 | 25.00 | 21.65 | G, P, E | |

| 4S4 | 12.70 | 40.48 | 34.93 | G | |

| 4S6 | 12.70 | 31.75 | 27.43 | P, G | |

| 5S4 | 15.87 | 38.00 | 32.91 | R |

All measurement in millimetres.

*Angle cut-off 56°19′ or defrosting slots ø 6.4 × 12 available.

Corrugations

P, S

plain fin

G, R

corrugated fin

E

louvere fin

LCE Coating

In 2012 LEEL Coils introduced a new technology of coating called LCE Coating. LCE Coating is a revolutionary technology that protects heat exchanger coils from corrosion, mould and bacteria in a very effective way. Unlike solvent-based coatings, LCE Coating is a water-based product that brings us two significant improvements: Super Hydrophobic effect and anti-microbial protection.

Process that guarantees 100 % penetration & protection. The entire coil is immersed into a liquid form of LCE Coating letting the liquid penetrate even the smallest spaces between fins including fin collar, louvre, heat slots or any other type of forming.

Tests found 100 % penetration on fin blocks with 16 fins per inch (1,58 mm)!

In addition, all other parts like U-bends, end-plates, side plates, headers, capillaries are coated and protected as well.

LCE Coating benefits:

- Increases the lifetime of your units in highly aggressive environments

- Anti-microbial protection prevents bacteria from growing inside your units

- Repairable-on-site coating

- No impact on capacity

- 100 % penetration inside coil due to total immersion application

- Super hydrophobic surface

- Coating with strong bond to the substrate surface

Anti-corrosion solution that actually works, LCE Coating makes a protective elastic layer on the whole surface of the coil. This layer is capable of withstanding thermal dilatation of the coil without cracking. Elasticity is a critical ability to prevent the creation of small cracks where corrosion begins. With this ability we can be sure that the protection works while the unit is working in real conditions.

NO MORE CORROSION

Many air units are working in aggressive environments such as ocean coast, food production lines, animal shelters, piggery units and so on where standard protection isn’t enough. LCE Coating offers perfect solution for coils in such environments.

Certificated from tests performed on single sheet metal samples

- Passed ASTM B117 (Salt spray test) 10 000 hours in heating/cooling cycles changing temperatures between 60 °C and 5°C

- Passed ASTM G85:A1 (Acetic Acid-Salt spray test) to prove positive impact on coils used in food industry

- Passed ASTM G87 (SO2 test) the same as G85, only in usage acidic SO2 electrolyte

- Passed ASTM D552 (Flexibility test) to demonstrate the adhesion of the surface of the protective layer to the substrate surface of the coil

- Passed ASTM G85:A5 (Indirect spraying of dilute salt and ammonium sulphate) at 23°C and followed by 1 hour exposure of dry air at 35°C. Test proving resistance in salt containing environment and industrial applications

- Passed ASTM G21 (Test for resistance to mold and fungi) important aspect for evaporators

© 2025 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.