WELCOME TO THE WORLD OF COMPRESSOR TECHNOLOGY – THINK GREEN – CHOOSE BLUE

BOCK is one of the world’s technology and innovation leaders in the development of environmentally friendly, economical solutions in the field of refrigeration and air conditioning technology, including heat pumps and heat recovery – with one of the world’s largest portfolios of compressors for natural refrigerants such as CO2 (R744), hydrocarbons and other low-GWP refrigerants.

It is more than obvious that the world climate is constantly changing. Our planet is getting hotter and hotter and in our digital world we can observe these effects every day. Already today, 15% of the world’s electricity consumption is used for refrigeration and air conditioning. The way we deal with cold will therefore become increasingly important.

Bock has been developing compressors for the natural refrigerant CO2 (R744) since 1993. Their compressor range for hydrocarbons (HC) has the best reputation worldwide. And in the synthetic refrigerant sector, all their expertise is invested in the further development of compressors with low-GWP refrigerants, which is why we can confidently say: “Think green, choose blue”.

Southern Sales & Services are the UK’s largest distributor of Bock compressors, so if you have an enquiry that you think that we can help with, then please do not hesitate to contact us by phone or through our online quick contact form at the bottom of the page.

- HG Compressors

- HG LG Compressors

- HG UL Compressors

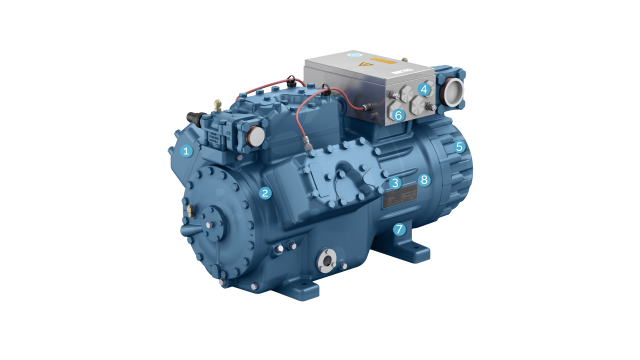

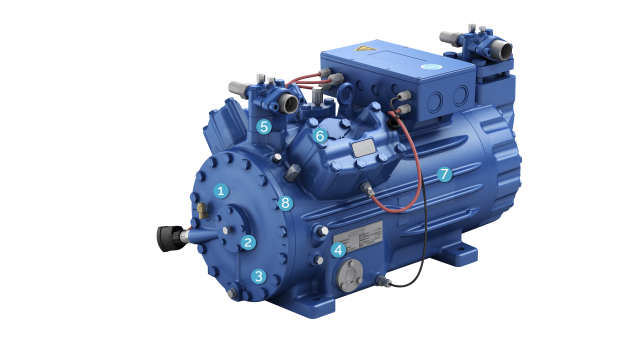

Bock HG Compressors

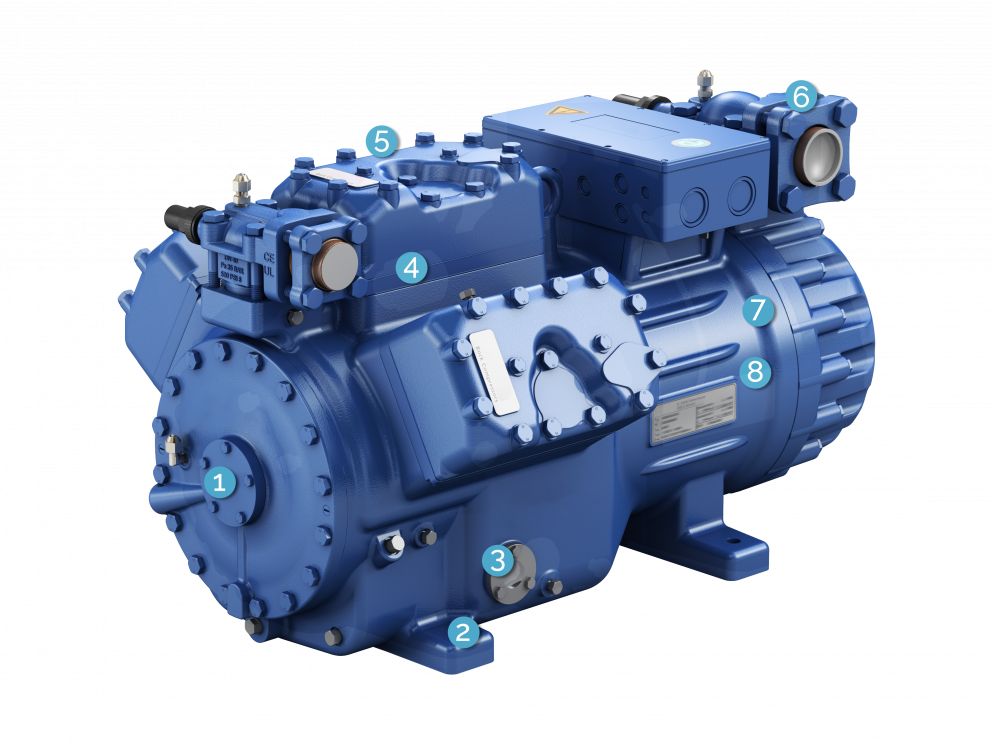

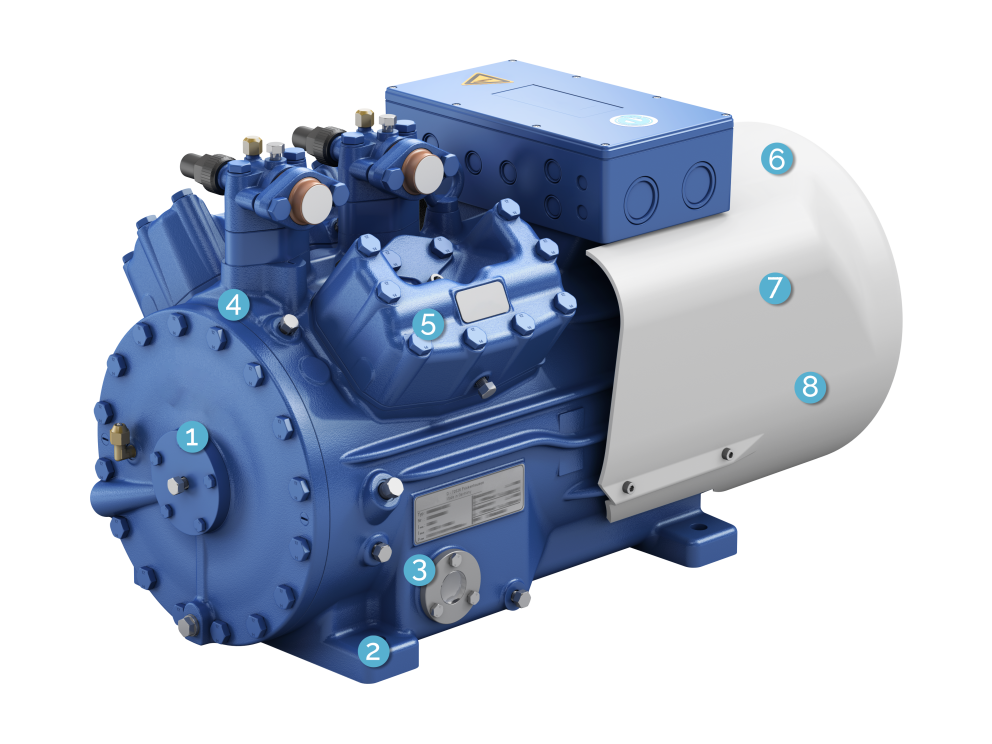

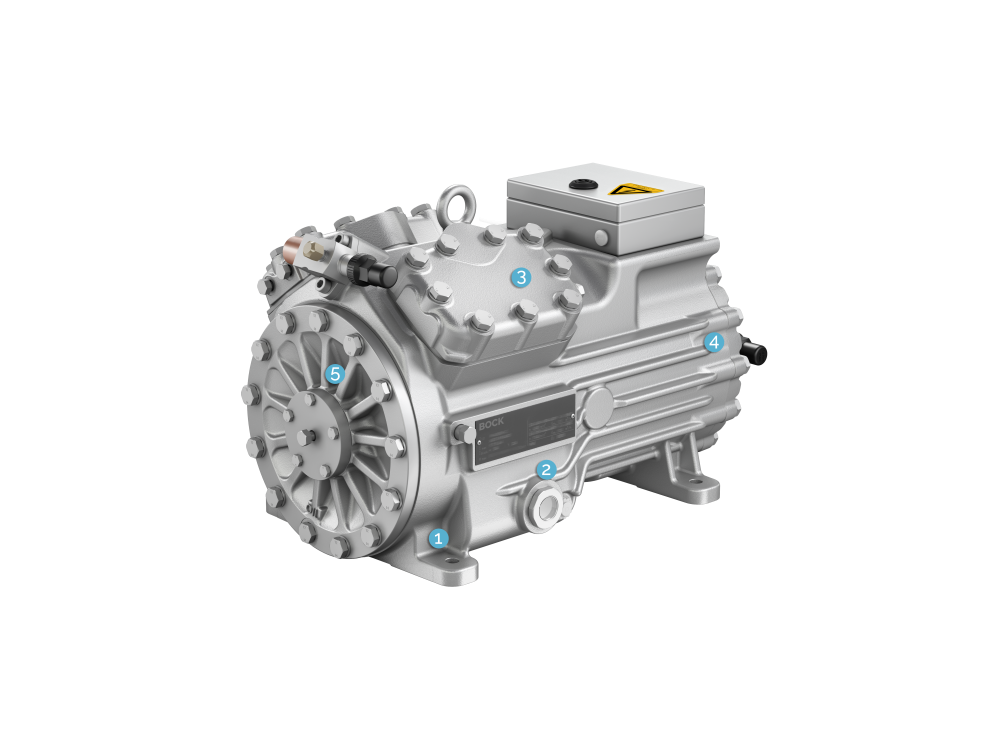

The Bock HG series is based on a classic design with state of the art suction gas-cooled, compressor technology. Smooth running, service-friendliness, high performance and reliability are the distinguishing features of these modern compressors.

Bock semi-hermetic compressors have been completely optimised to achieve efficiency gains. The new models feature an “e” indicating greater efficiency, mechanical improvement, compact design and user-friendly connections.

FEATURES

- Excellent running smoothness

- Efficiency and reliability at the highest quality level

- Service-friendly design, for example due to interchangeable drive motors

- Oil pump lubrication

- Electronic motor protection

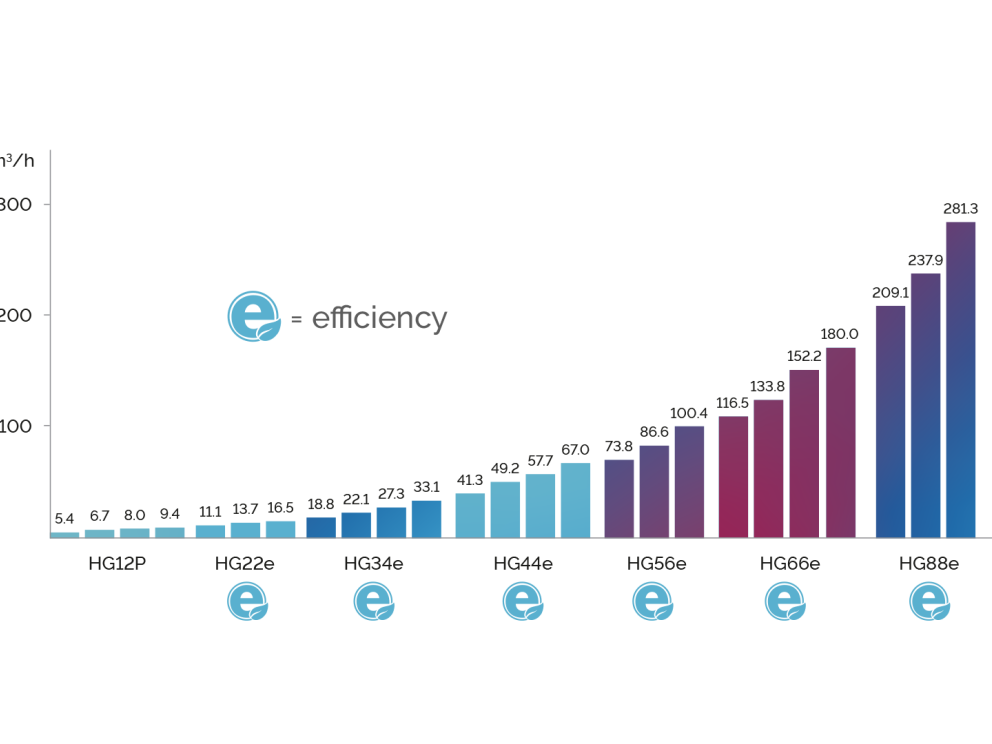

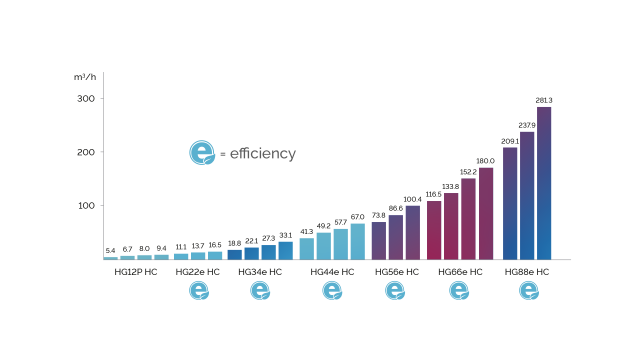

(Models: HG12P, HG22e, HG34e, HG44e, HG 56e, HG66e, HG88e)

TECHNICAL

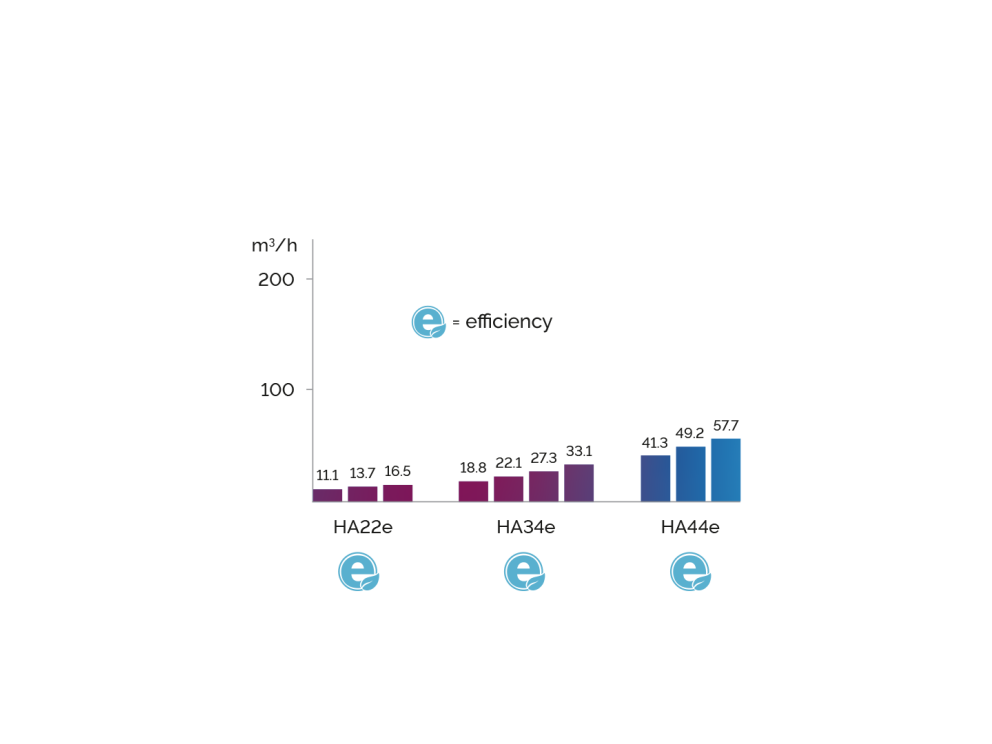

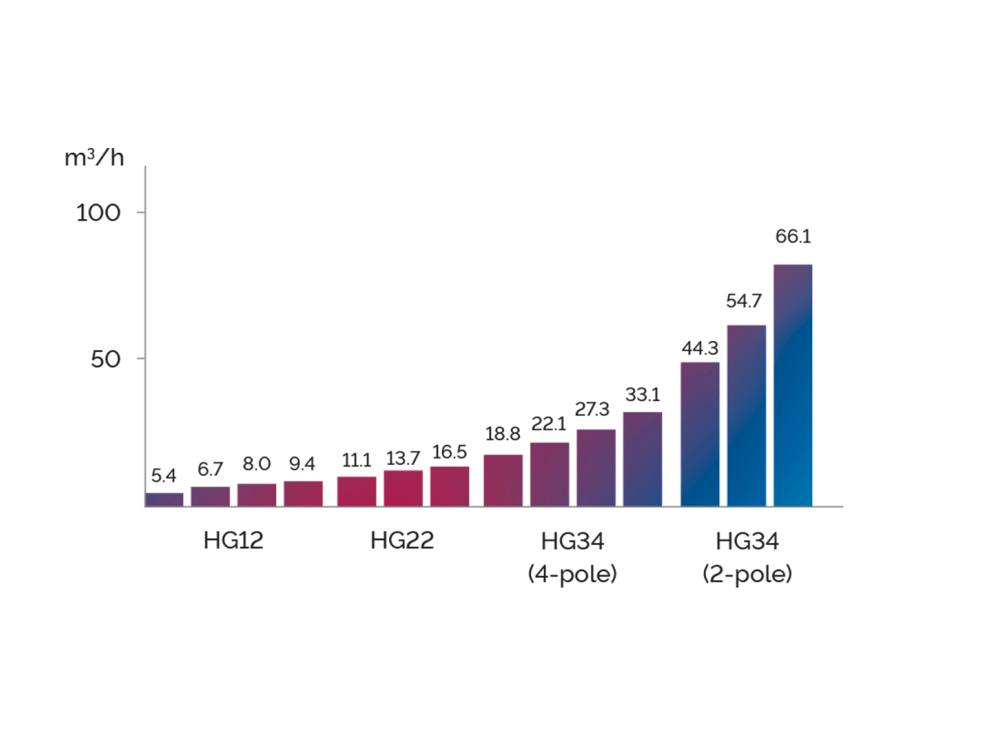

| Types | Displacement at 50 Hz (1450 rpm) m³/h | Former types |

| HG12P | 5.4 6.7 8.0 9.4 | |

| HG22e | 11.1 13.7 16.5 | HG22e (up to DK 056) HG22P |

| HG34e | 18.8 22.1 27.3 33.1 | HG34e (up to DK 056) HG4 |

| HG44e | 41.3 49.2 57.7 67.0 | HG4 HG44e (up to DK 056) HG5 |

| HG56e | 73.8 86.6 100.4 | HG5 HG6 |

| HG66e | 116.5 133.8 152.2 180.0 | HG6 HG7 |

| HG88e | 209.1 237.9 281.3 | HG8 |

More information about the HG single-stage compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

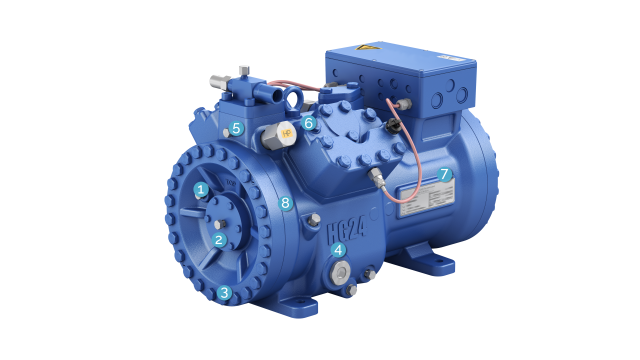

PRODUCT QUICK-CHECK

- Proven and reliable oil pump lubrication

- Standard footprints

- Standard-position sight glass

- mexxFlow® 2.0 valve plate system

- Newly designed housing with optimized gas flow

- Standard-position valves

- Highly efficient electric motors of the latest generation

- Exchangeable motor

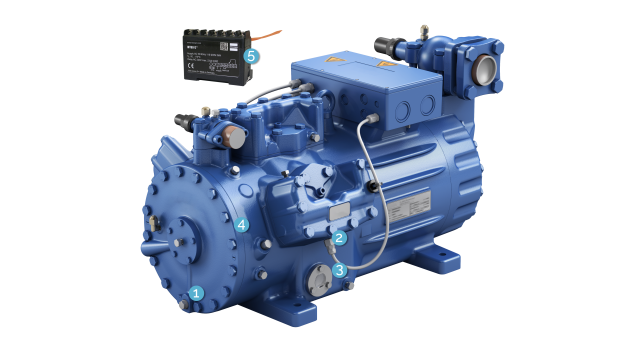

Bock LG Compressors

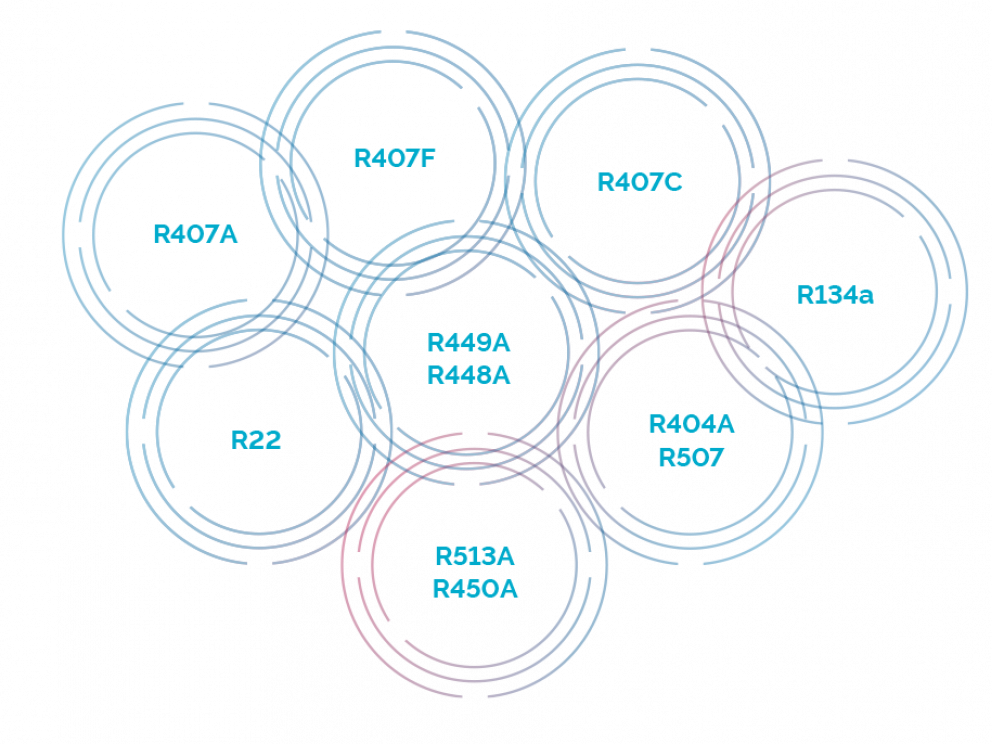

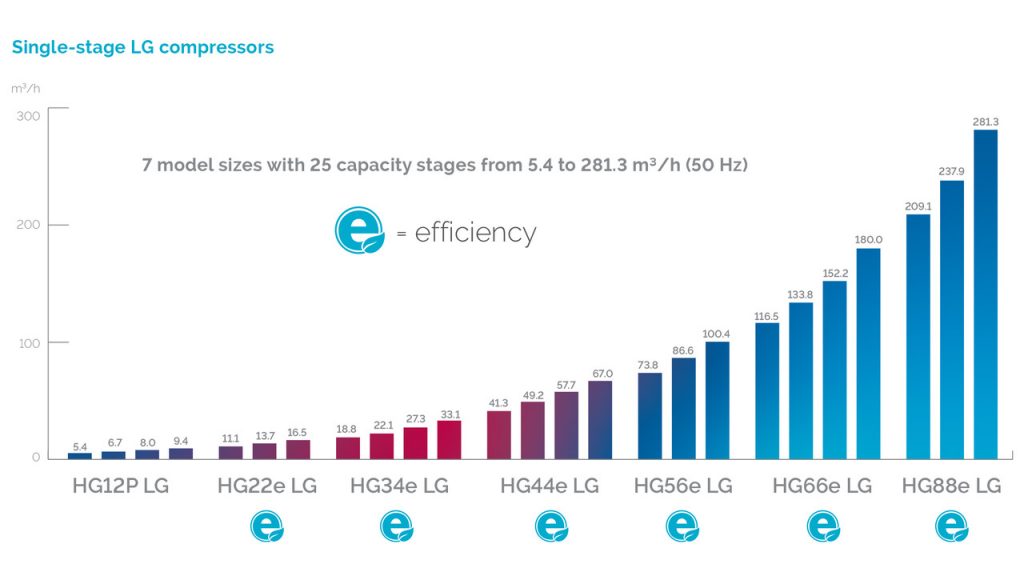

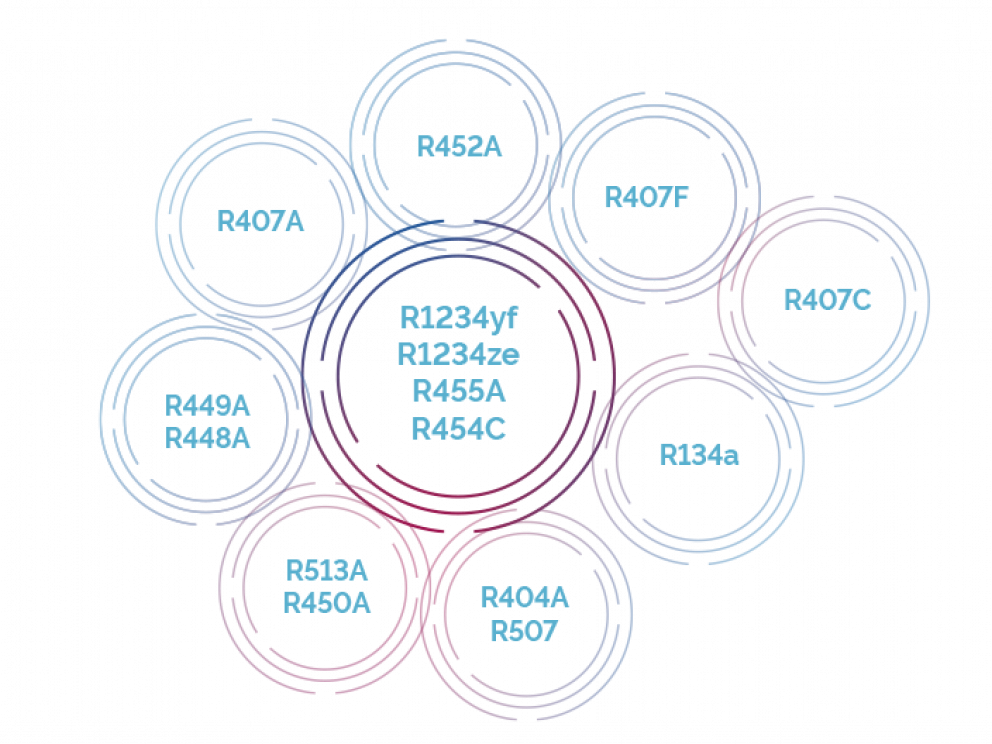

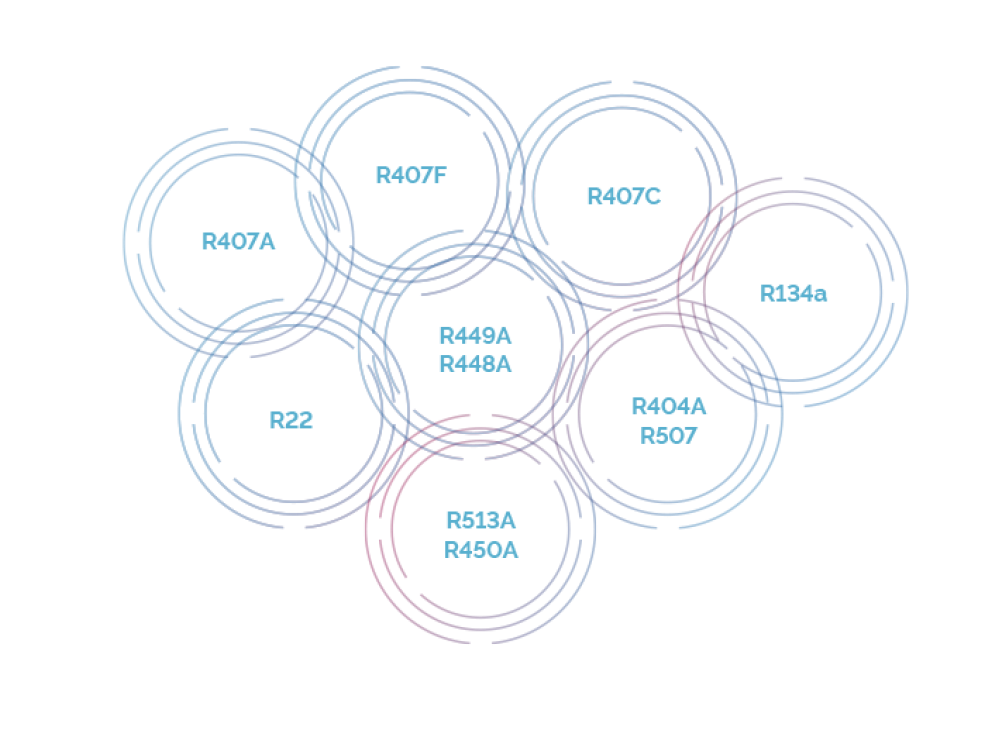

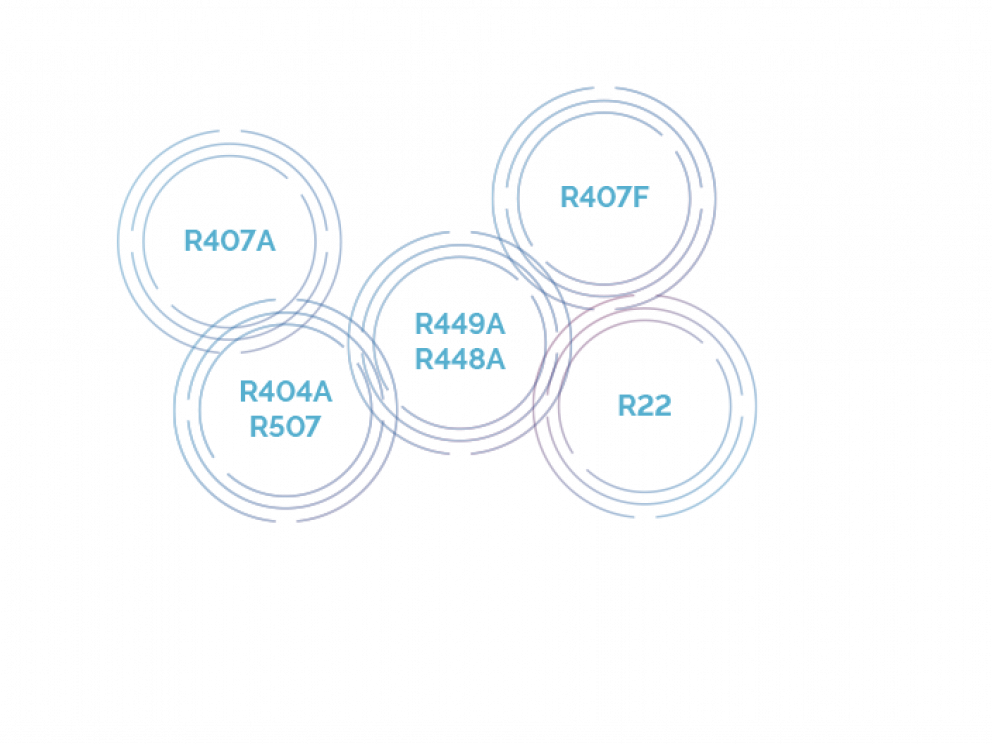

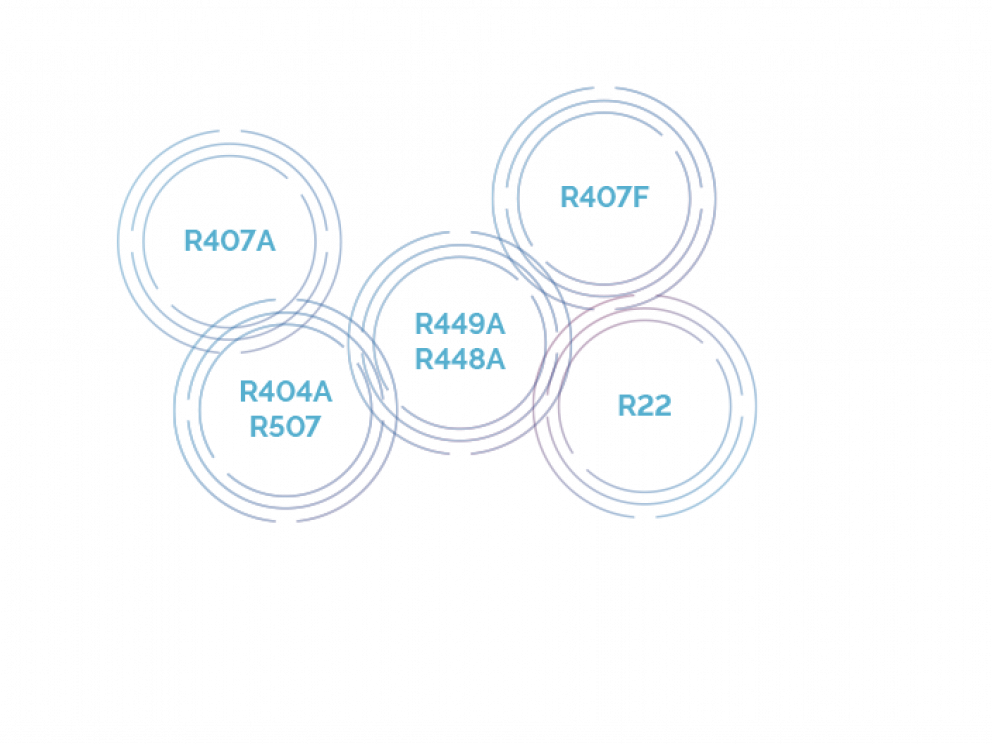

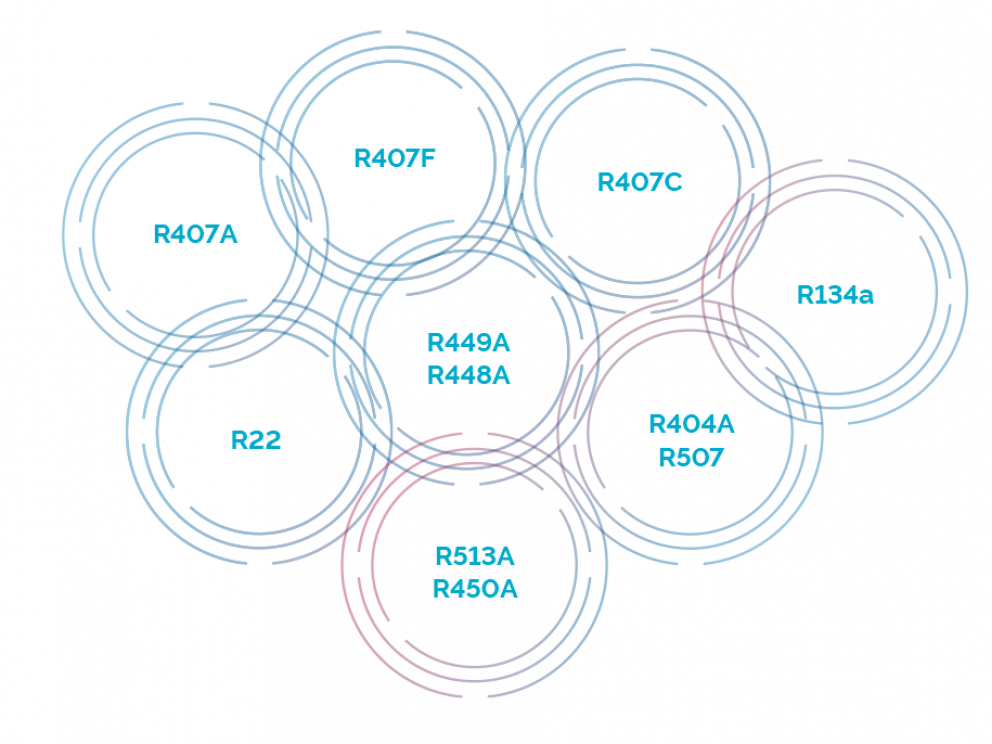

The series comes in seven model sizes with 25 capacity stages: With the new LG range (LG = Low GWP), which has been specially designed for use with low-GWP HFO refrigerants, the refrigeration and air-conditioning specialist Bock will in future offer a semi-hermetic compressor portfolio with suitable compressor technology for all synthetic refrigerants. This includes both the common HFC fluids and the new HFO low-GWP fluids with a GWP value of less than 150.

FEATURES

- HFO refrigerants require special compressor technology: Long-term tests in various refrigeration applications internally and externally.

- More functional reliability

- LG compressors are a separate series based on the semi-hermetic, suction gas-cooled HG compressor range

- Optimized Driving Gear: more resistant compressors to decreasing oil viscosity

- Solution for low-GWP HFO refrigerants: only one compressor version for all common refrigerants

TECHNICAL

HGX LG (suction gas-cooled)

HG LG (Low GWP) single-stage compressors

The HG – LG model series consists of state-of-the-art classical suction gas-cooled compressor technology.

- Suitable for HFO (safety class A2L) as well as chlorine-free HFC refrigerants (A1)

- Optimized drive for demanding use with HFO refrigerants

- Seal materials suitable for operation with HFO and HFC refrigerants

- Electronic motor protection included for installation in an external switch cabinet

- When being used in evaporation temperatures greater than +15°C, the ester oil C85E must be used

- Outstanding running comfort

- Efficiency and reliability on the highest level of quality

- Service-friendly, e.g. replaceable drive motors

- Oil pump lubrication

HG…e

Those compressors are efficiency optimised models.

By technical optimisations the motor-efficiency, gas flow and efficiency of the valve system are improved.

More information about the HG single-stage compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Special sealing materials

- Optimized power unit

- Special oil filling for heat pump application

- Motor protection (device as accessory)

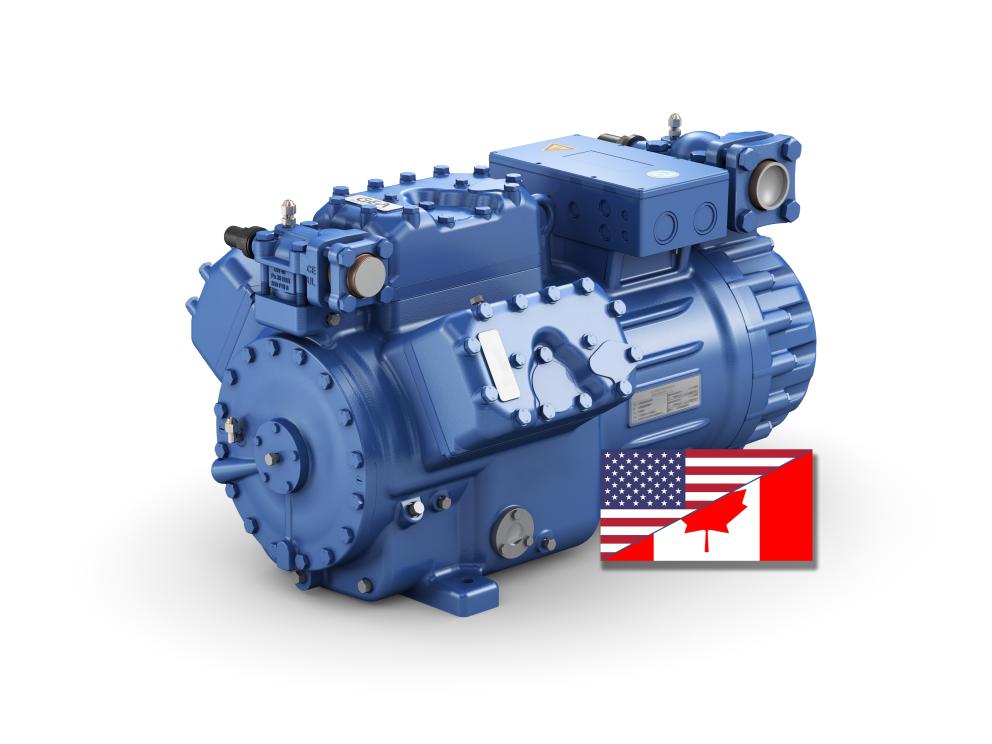

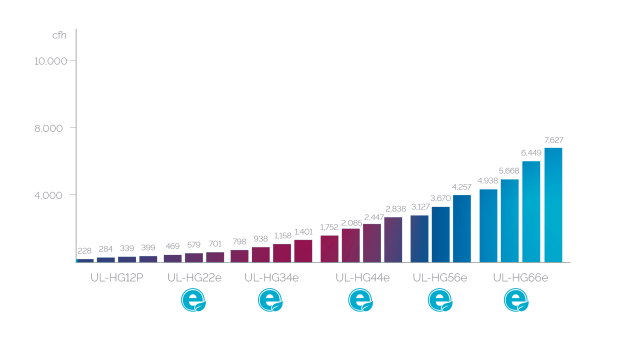

Bock UL compressor range

UL extension for BOCK HG compressors: Approved for US and Canadian safety standards

The new UL-HGe series is a stand-alone series that combines all the advantages of the standard semi-hermetic HGe series with the specific UL requirements. UL stands for the U.S. company “Underwriters Laboratories (UL)”. It tests and certifies products about their safety.

UL standards encompass UL’s safety research and scientific expertise. In addition to the UL certification, the new BOCK compressor series is very energy-efficient (e-marking in the type code), robust and compact.

The BOCK UL-HGe compressors are suitable for a wide range of applications using chlorine-free HFC refrigerants. The usual running comfort, easy maintenance, reliability, and the typical Bock quality standards also characterise this compressor series.

The BOCK configuration tool VAP offers you the possibility to find the right compressor and cooling solution according to your project

TECHNICAL

More information about the HG UL compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Proven and reliable oil pump lubrication

- Standard footprints

- Standard-position sight glass

- mexxFlow® 2.0 valve plate system

- Newly designed housing with optimized gas flow

- Standard-position valves

- Highly efficient electric motors of the latest generation

- Exchangeable motor

- HA Compressors

- HA LG Compressors

Bock HA Compressors

The HA-system – the best solution for deep-freezing! The semi-hermetic HA series from BOCK was specially developed for low temperature cooling and prevents excessively high final displacement temperatures. The drive motor and cylinder heads of this reciprocating compressor are air-cooled via a compact ventilation unit. The refrigerant gas is sucked in and condensed directly by the compressor.

FEATURES

- Compressor operates with direct suction, motor is air-cooled

- Suction gas is not additionally heated by the motor, but is sucked in directly by the compressor via the motor.

- Motor cooling via compact ventilation unit

- Targeted air cooling of engine and cylinder heads

- Compressed gas temperature is reduced

- Significant increase in performance

- Extension of the application range

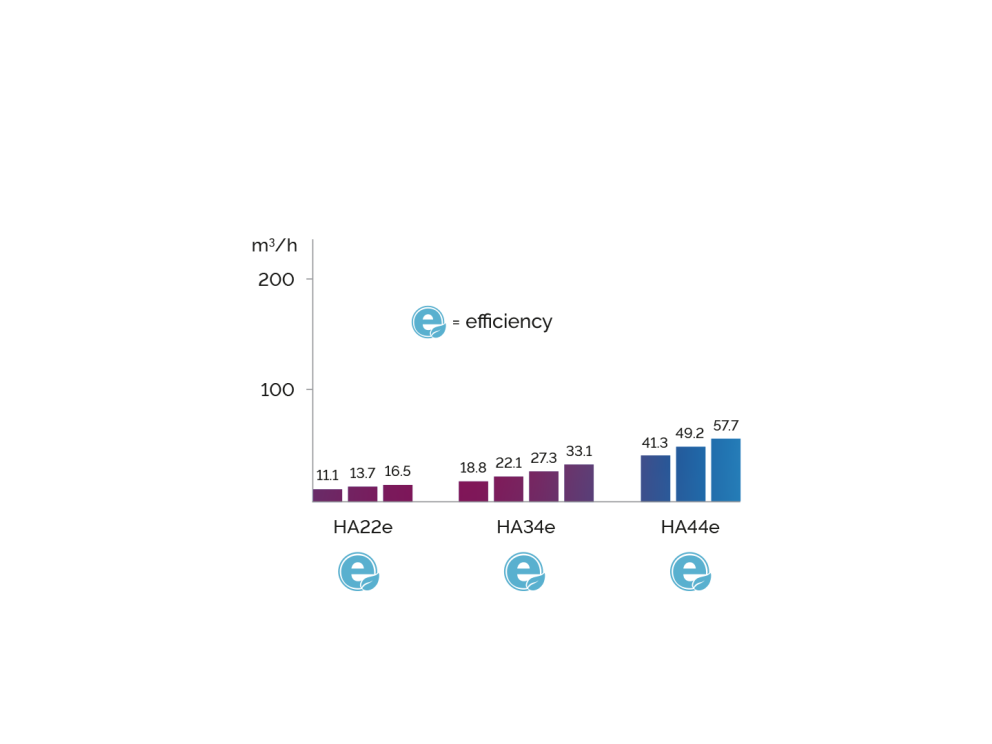

TECHNICAL

More information about the HA LG single-stage compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Proven, reliable oil pump lubrication system

- Standard mounting position

- Standard position sight glass

- New designed housing with optimized gas guide

- Optimized valve plate system

- External fan for motor cooling

- Highly efficient electric motors of the latest generation

- Replaceable motor

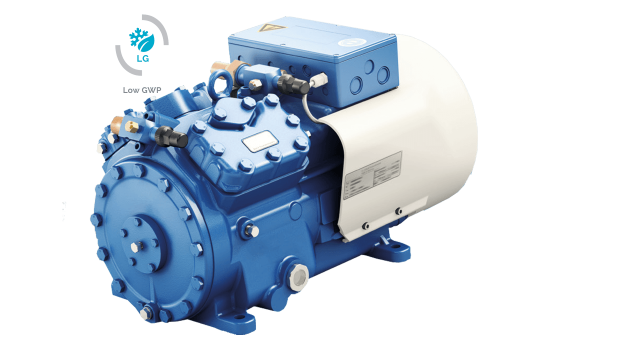

Bock HA LG (Low GWP) single-stage compressors

The HA – system – the best solution for deep-freezing! The semi-hermetic HA series from BOCK was specially developed for low temperature cooling and prevents excessively high final displacement temperatures. The drive motor and cylinder heads of this reciprocating compressor are air-cooled via a compact ventilation unit. The refrigerant gas is sucked in and condensed directly by the compressor.

FEATURES

- Suitable for HFO (safety class A2L) as well as chlorine-free HFC refrigerants (A1)

- Optimized drive for demanding use with HFO refrigerants

- Seal materials suitable for operation with HFO and HFC refrigerants

- Electronic motor protection included for installation in an external switch cabinet

- Direct intake with external ventilation

- Suction gas intake directly into the compressor

- Motor cooled by an integrated ventilation unit

This reduces the compressed gas temperature and thus expands the range of application while at the same time increasing capacity. At the same time, the compressor is physically separated from the compressor, with advantages particularly in the case of motor damage.

TECHNICAL

More information about the HA single-stage compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Proven, reliable oil pump lubrication system

- Standard mounting position

- Standard position sight glass

- New designed housing with optimized gas guide

- Optimized valve plate system

- External fan for motor cooling

- Highly efficient electric motors of the latest generation

- Replaceable motor

- HG ATEX Compressor

- HG HC Compressors

Bock HG ATEX Compressors

Bock is the first European manufacturer to offer semi-hermetic compressors certified according to ATEX machine category 2 (zone 1+2). In 2014, Bock also included compressors certified according to ATEX machine category 3 (zone 2) in its program. Within the European Union, electrical and mechanical machinery operated in explosive atmospheres must comply with the so-called ATEX (ATmospheres EXplosibles) conditions. All ATEX compressors are also approved for operation with the current hydrocarbons. The models in the HG Series are the basic compressors for ATEX versions.

The models in the HG Series are the basic compressors for ATEX versions.

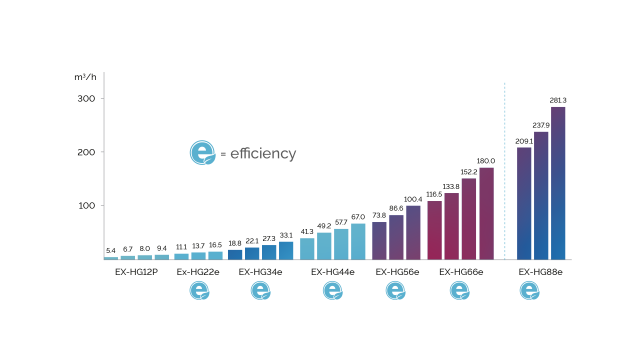

TECHNICAL

HG ATEX 2G (Zone 1+2)

| Types | Displacement at 50 Hz (1450 rpm) m³/h | Former types |

| EX-HG12P | 5.4 6.7 8.0 9.4 | |

| EX-HG22e | 11.1 13.7 16.5 | EX-HG22e (up to DK 056) |

| EX-HG34e | 18.8 22.1 27.3 33.1 | EX-HG34e (up to DK 056) |

| EX-HG44e | 41.3 49.2 57.7 67.0 | EX-HG4 EX-HG5 |

| EX-HG56e | 73.8 86.6 100.4 | EX-HG5 EX-HG6 |

| EX-HG66e | 116.5 133.8 152.2 180.0 | EX-HG6 EX-HG7 |

HG ATEX 3G (Zone 2)

More information about the HG ATEX compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Monitoring of all cylinder covers with special

thermal protection thermostats (zone 1: included in delivery) - 2 Paint finishes:

ESD paint (explosion subgroup IIC)

Polyurethane-free offshore paint (explosion subgroup IIB) - Classification of the compressor in temperature class T3

- Explosion-proof design of the electrical components

- Potential equalisation connection

- Explosion-proof terminal box

- Explosion-proof accessories available

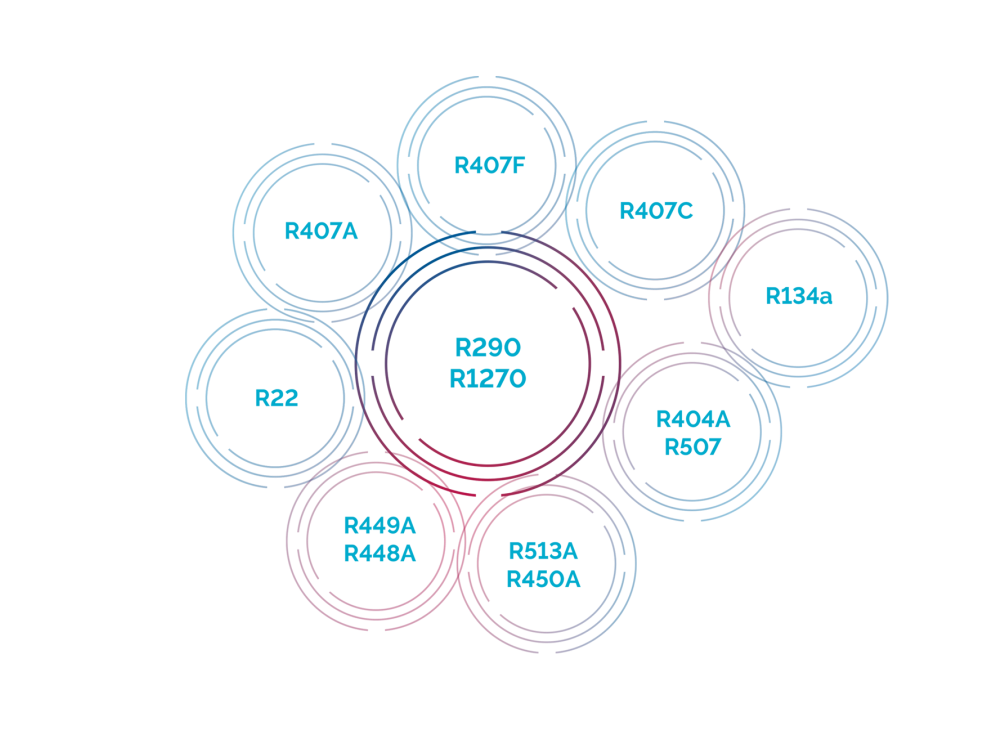

Bock HG HC Compressors

FEATURES

- For various applications, such as the field of supermarket refrigeration, hydrocarbons have established themselves as another natural alternative besides CO2.

- Due to the flammability of hydrocarbons the compressor has some safety related modifications.

TECHNICAL

HG HC Standard

| Types | Displacement at 50 Hz (1450 rpm) m³/h | Former types |

| HG12P | 5.4 6.7 8.0 9.4 | |

| HG22e | 11.1 13.7 16.5 | HG22P (up to DK 056) |

| HG34e | 18.8 22.1 27.3 33.1 | HG34P (up to DK 056) |

| HG44e | 41.3 49.2 57.7 67.0 | HG44e (up to DK 056) |

| HG56e | 73.8 86.6 100.4 | HG5 HG6 |

| HG66e | 116.5 133.8 152.2 180.0 | HG6 HG7 |

| HG88e | 209.1 237.9 281.3 | HG8 |

More information about the HG HC compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

HG HC ATEX 2G (Zone 1+2)

| Types | Displacement at 50 Hz (1450 rpm) m³/h | Former types |

| EX-HG12P | 5.4 6.7 8.0 9.4 | |

| EX-HG22e | 11.1 13.7 16.5 | EX-HG22e (up to DK 056) |

| EX-HG34e | 18.8 22.1 27.3 33.1 | EX-HG34e (up to DK 056) |

| EX-HG44e | 41.3 49.2 57.7 67.0 | EX-HG4 EX-HG5 |

| EX-HG56e | 73.8 86.6 100.4 | EX-HG5 EX-HG6 |

| EX-HG66e | 116.5 133.8 152.2 180.0 | EX-HG6 EX-HG7 |

More information about the HG HC ATEX compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

VAP compressor selection HG HC ATEX compressors for Zone 1+2

HG HC ATEX 3G (Zone 2)

More information about the HG HC ATEX compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Oil sump heater (necessary)

- Thermal protection thermostat (recommended)

- Special oil charge with BOCKlub G68 (PAG)

- Durable driving gear

- Electronic motor protection enclosed for installation in the switch cabinet

- HG Aluminium Compressors

- HG 2-pole Compressors

- HGZ Two-stage Compressors

Bock HG Aluminium Compressors

Suction gas cooled aluminium reciprocating compressors from BOCK, based on the classic HG compressor series in grey cast iron, are specially designed for mobile refrigeration applications due to their lightweight construction.

They are approx. 40% lighter and have a reduced overall height, making them particularly suitable for roof mounting on vehicles. Together with the robust K-design valve plate, which was specially developed for bus air conditioning, they are the first choice for electric applications. With the special oil management, the mobile aluminium compressors are also suitable for large inclination angles.

FEATURES

- Particularly powerful and compact due to 2-pole drive motor (2,900 1/min – 50 Hz)

- Even more compact: reduced overall height of 300 mm due to optional terminal box

- Lockable metal terminal box for access restriction

- Terminal blocks with increased serviceability and railroad approval, shock and vibration resistant

- Fire protection class HL3 according to railroad standard EN 45545-2 also with special track painting

- Pressure lubrication with oil pump as standard

- Electronic motor protection

TECHNICAL

More information about the HG Alu compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- 40% lighter than cast iron version due to lightweight aluminum construction

- Power control also possible digitally in wide bandwidth

- Reliable and efficient reciprocating piston technology with optimized valve plate system and low oil throw

- Highly efficient 4-pole and 2-pole electric motors

- Wear-resistant and durable power unit

Bock HG 2-pole Compressors

Based on the HG standard compressors with their outstanding advantages and features, versions with 2-pole drive motor are available with up to 70% increased cooling capacity with the same external dimensions. This is made possible by doubling the speed at the same mains frequency. Together with the robust and reliable BOCK K valve plate, this results in the optimal solution for bus air conditioning and many other mobile applications.

FEATURES

- Particularly powerful and compact due to 2-pole drive motor (2,900 1/min – 50 Hz)

- Even more compact: reduced overall height of 300 mm due to optional terminal box

- Lockable metal terminal box for access restriction

- Terminal blocks with increased serviceability and railroad approval, shock and vibration resistant

- Fire protection class HL3 according to railroad standard EN 45545-2 also with special track painting

- Pressure lubrication with oil pump as standard

- Electronic motor protection

TECHNICAL

More information about the HG 2-pole compressors (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- 40% lighter than cast iron version due to lightweight aluminum construction

- Power control also possible digitally in wide bandwidth

- Reliable and efficient reciprocating piston technology with optimized valve plate system and low oil throw

- Highly efficient 4-pole and 2-pole electric motors

- Wear-resistant and durable power unit

Bock HGZ Two-stage Compressors

Based on the HG series, BOCK has developed a two-stage compressor series for extended use in low temperature cooling. The HGZ compressor series provides a 6-cylinder compressor which is currently available in two versions. The HGZ compressor is alternatively available with a medium-pressure mixing line as an accessory or as an already mounted version.

FEATURES

- 6-cylinder version

- LP/HP stage split in a ratio of 2:1

- Two-stage operation with liquid subcooler

- Post-injection valve matched to refrigerant and application

- Particularly reliable and economical compressor concept

TECHNICAL

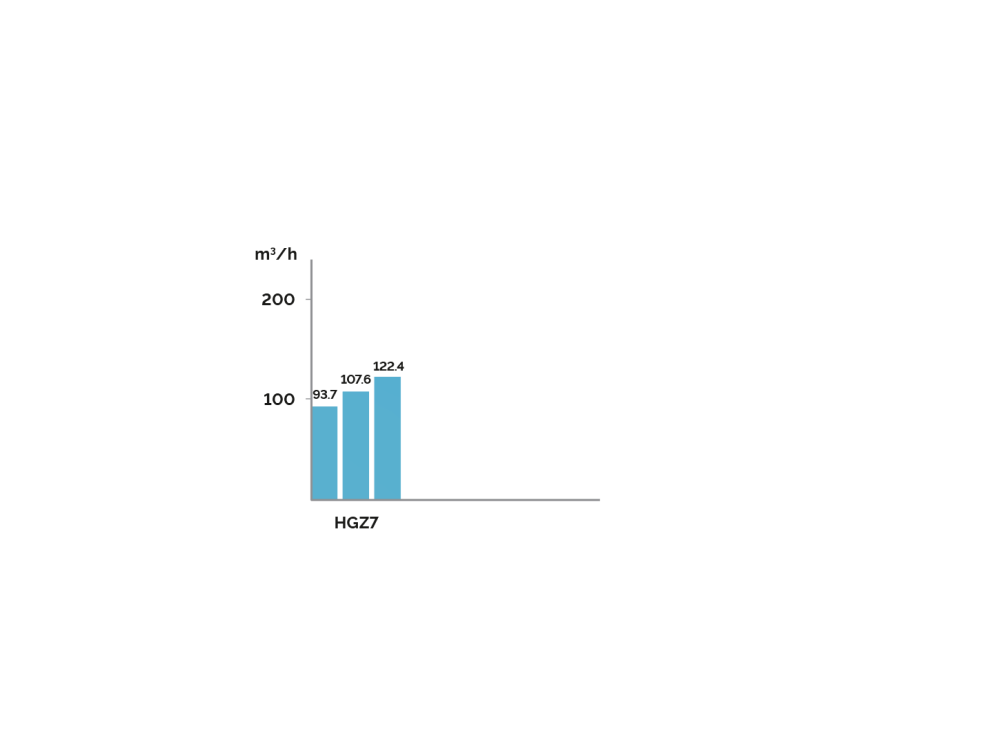

| Types | Displacement at 50 Hz (1450 rpm) m³/h |

| HGZ7 | 93.7 / 46.9107.6 / 53.8122.4 / 61.2 |

| HGZX7 | 93.7 / 46.9107.6 / 53.8122.4 / 61.2 |

More information about the SHGZ two-stage condensing units (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

PRODUCT QUICK-CHECK

- Subcooler

- Post-injection valve

- Solenoid valve

- Suction gas line connection

- Liquid line connection

- HG Transcritical CO2

- HG Subcritical CO2

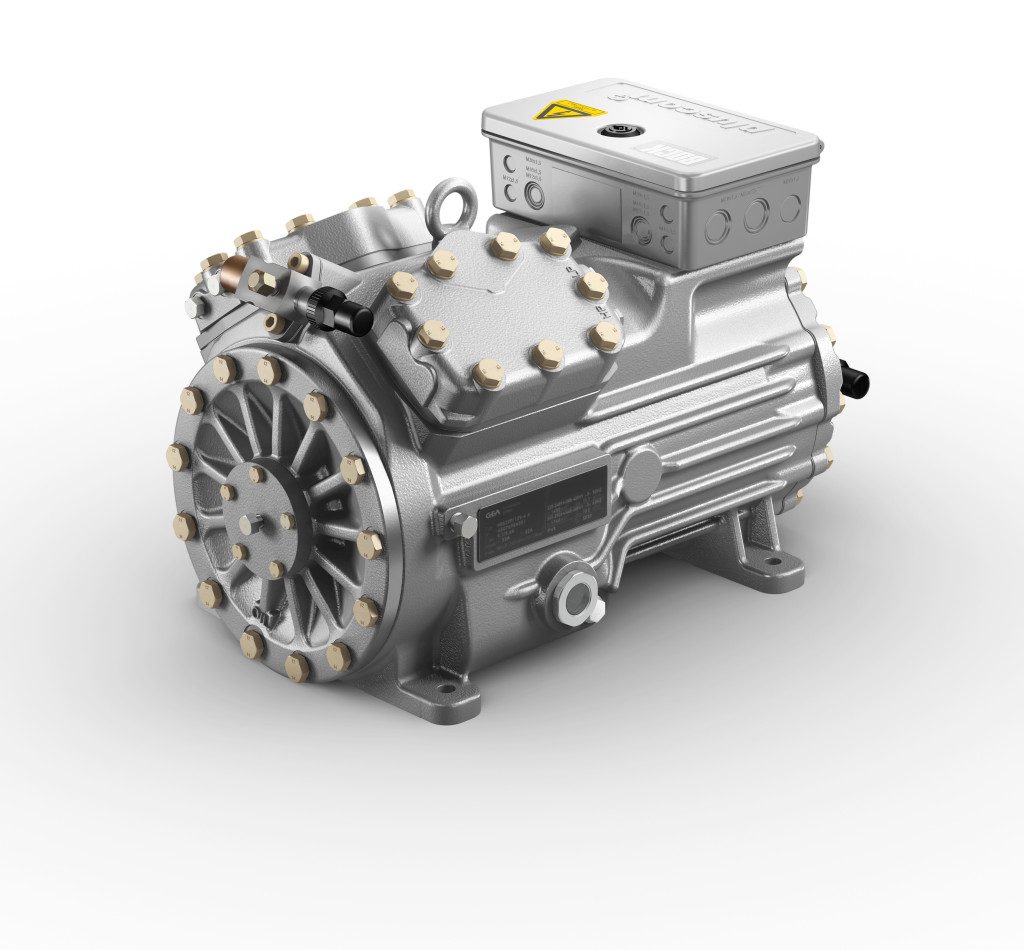

Bock HG Transcritical CO2 Compressors

With their optimised efficiency, the gas-cooled semi-hermetic CO2 compressors achieve the highest EER/COP values within their range of applications – officially confirmed by ASERCOM (Association of European Refrigeration Component Manufacturers) certification for several displacement stages.

Further advantages of reciprocating compressors include the highest reliability and durability.

FEATURES

- Flexible use for cascade and booster CO2 systems.

- Supermarket applications: food refrigeration and air conditioning

- Commercial and industrial refrigeration systems

- Wide use for deep freeze applications

- Heat pumps

- Mobile applications: Air conditioning & heat pumps in buses and trains

TECHNICAL

More information about the HG CO2 compressors transcritical (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

More information about the HG CO2 compressors transcritical (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

VAP compressor selection HG CO2 compressors transcritical (LSPM)

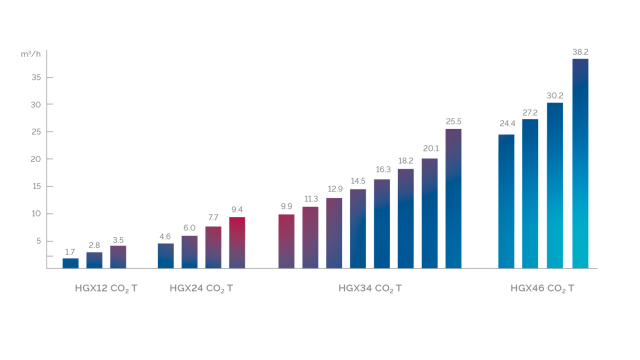

PRODUCT QUICK-CHECK

- Frequency range 20 (30) – 70 Hz

- Oil pump for reliable lubrication system

- Compact dimensions and standard connections

- Low weight, maximum permissible inclination

- Lowest oil carry over rate

- Displacement at 50 Hz: 1.7 to 38.2 m³/h

- Wide capacity range

- CO2-specific pressure design LP/HP: 100 /150 bar

VIDEO

Video about the BOCK CO2 compressor program

Bock HG Subcritical CO2 Compressors

Based on our current semi-hermetic product range, with its outstanding advantages and features, as well as the derived and long-used basic range, there is now a perfectly matched compressor series available for use with CO2 in sub-critical cascade systems.

They are particularly suited to supermarket applications and industrial cooling systems.

FEATURES

- Flexible use for cascade and booster CO2 systems.

- Supermarket applications: food refrigeration and air conditioning

- Commercial and industrial refrigeration systems

- Wide use for deep freeze applications

- Heat pumps

- Mobile applications: Air conditioning & heat pumps in buses and trains

TECHNICAL

More information about the HG CO2 compressors subcritical (e.g. technical/performance data, drawings, spare part lists, operating limits) can be found in the compressor selection tool VAP via the following link:

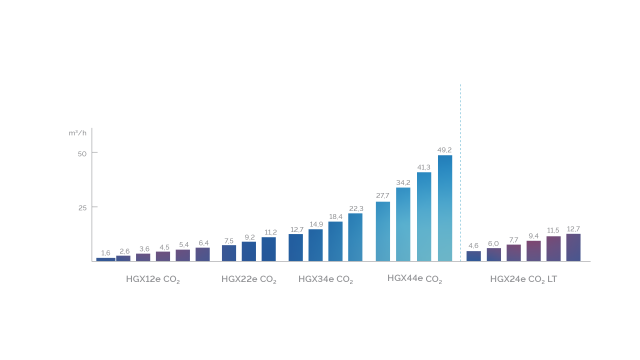

PRODUCT QUICK-CHECK

- Frequency range 25 (30) – 70 Hz

- 2Oil pump for reliable lubrication system

- Compact dimensions and standard connections

- Low weight, maximum permissible inclination

- Lowest oil carry over rate

- Displacement at 50 Hz: 1.6 to 49.2 m³/h

- Wide capacity range

- Co2-specific pressure design LP/HP: 40 (30) / 55 bar

VIDEO

Video about the BOCK CO2 compressor program

NOTE: In March 2021, BOCK was separated from the GEA Group. BOCK now trades as an independent company: BOCK Gmbh.

We continue to provide all of the BOCK products formerly produced under the GEA Group. As always we will aim to provide excellent advice and product support and can help with any enquiries you have regarding the transition or any products affected.

© 2025 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.