Strengthened by a recent alliance with fellow manufacturer Unicla, Sanden has introduced a co-branded portfolio of larger capacity heavy – duty compressors.

Southern Sales & Services are the main distributor for the UK and Ireland. We supply Unicla Sanden compressors and accessories for all your application requirements. If you only need to replace your worn out compressor or you would like to retrofit your current system, or even have a requirement for large quantities for production, then we cater for all your needs.

If you need more information or have any questions, we’d be pleased to hear from you.

200 Series Compressors

The Sanden 200 series compressors are designed to meet the demands of larger mid-range single and twin air-conditioning systems, and refrigeration applications where the system capacity requirement is 6-11 kW. Many transport refrigeration and air-conditioning systems in service today have compressors that are either too small or too large.

The Sanden 200 series has always solved this ‘gap’ in compressor sizing and has continued to be known as the most reliable, highest capacity 200 cc compressor suitable for heavy duty transport refrigeration, military, marine, minibus, mining and agricultural applications.

The Sanden 200 series Hydraulic Drive compressors are universally adaptable and can be driven by any 11-15 cc hydraulic motor with a standard SAE twin-bolt A-type mounting configuration and 5/8” nine-tooth shaft. The unit can be supplied as a complete housing and compressor kit without the hydraulic motor, or the hydraulic drive housing kit on its own without the compressor.

- UP200 | UPF200

- UM200 | UMF200

- UX200 | UXF200

- UPH200 | UPHF200

Features

- Sanden 10-cylinder swashplate

- Suitable for applications with a system capacity requirement of 6-11 kW

- Displacement: 200 cc/rev

- Maximum continuous: 6000 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The UP and UPF models are compatible with mounting brackets designed for compressors with 80 mm lug spacings and can be interchanged with many compressors used in various applications.

Service valves

Low- and high-side service valves are fitted to the rear cap, including a high-pressure relief valve.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000010) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

Features

- Sanden 10-cylinder swashplate

- Suitable for applications with a system capacity requirement of 6-11 kW

- Displacement: 200 cc/rev

- Maximum continuous: 6000 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The UM and UMF model compressors feature a new mounting configuration of four conventional bolt-through mounting points that have been narrowed to 92 mm at the top and 87 mm at the bottom. They are directly compatible with TM21 and QP21 compressors.

Service valves

High-pressure relief valve fitted, service valves not fitted.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000010) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

Features

- Sanden 10-cylinder swashplate

- Suitable for applications with a system capacity requirement of 6-11 kW

- Displacement: 200 cc/rev

- Maximum continuous: 6000 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The UX and UXF models are direct mount (bolt-through) and have side mounting points 94 mm apart.

Service valves

Low- and high-side service valves are fitted to the rear cap, including a high-pressure relief valve.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000010) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

Features

- Sanden 10-cylinder swashplate

- Suitable for applications with a system capacity requirement of 6-11 kW

- Displacement: 200 cc/rev

- Maximum continuous: 6000 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The UPH and UPHF models are designed to mount to a solid base plate at four points equal to or greater than 185 x 80 mm in diameter.

Service valves

Low- and high-side service valves are fitted to the rear cap, including a high-pressure relief valve.

Oil return port

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is supplied as standard on both UPH and UPHF models. It has a unique flow design suited to the Sanden oil separator (Part No. OS000010) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

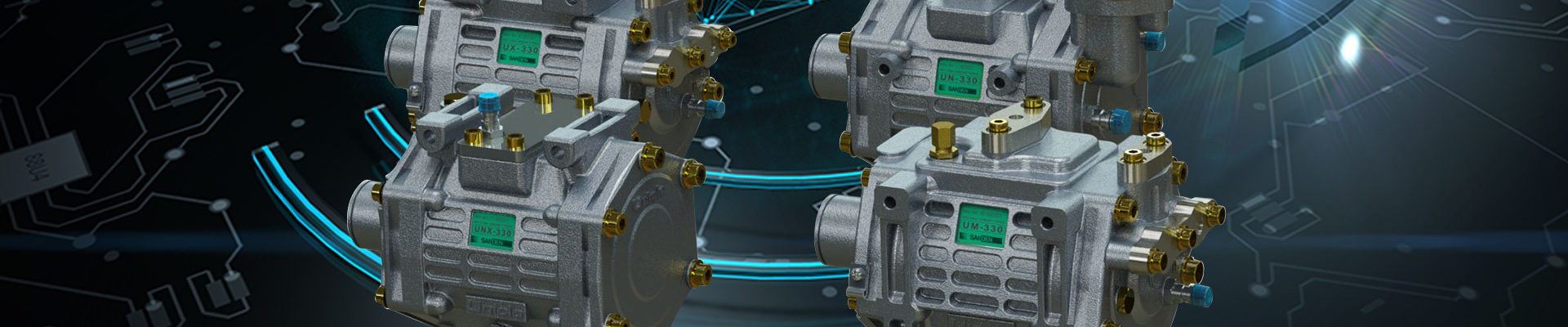

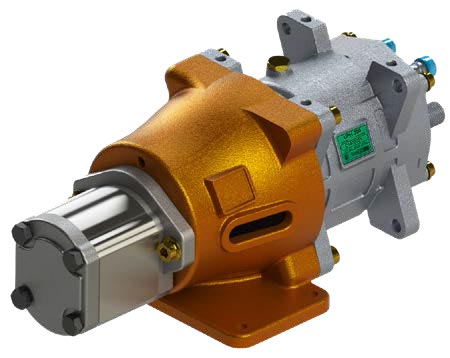

300 Series Compressors

The Sanden 300 series compressors are the ideal choice for designers of air-conditioning and refrigeration systems in larger commercial applications where the system capacity requirement is 10-16 kW. For systems with two or even three evaporators, Sanden 300 series compressors can be used as a single unit or mounted in twin or triple configurations. The 300 series has porting for horizontal or vertical hose connections as standard, and heavy duty blanking plates installed on outlets that are not in use.

These compressors feature the world-renowned Sanden 10-cylinder swashplate design that delivers extremely quiet and smooth operation with unbeatable volumetric efficiency through all revolution ranges – especially at low rpm – in either clockwise or counterclockwise direction.

- UX330 | UXF330

- UM330 | UMF330

- UN330

- UNX330

- UX380 | UXF380

- UM380 | UMF380

- UN380

- UNX380

UX330 | UXF330

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 10-14 kW

- Displacement: 330 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

Suited to all mounting brackets made for direct mount (boltthrough) compressors with bolt holes 104 mm apart, including four M10 x 1.5 mm threaded holes top and bottom 75 mm apart.

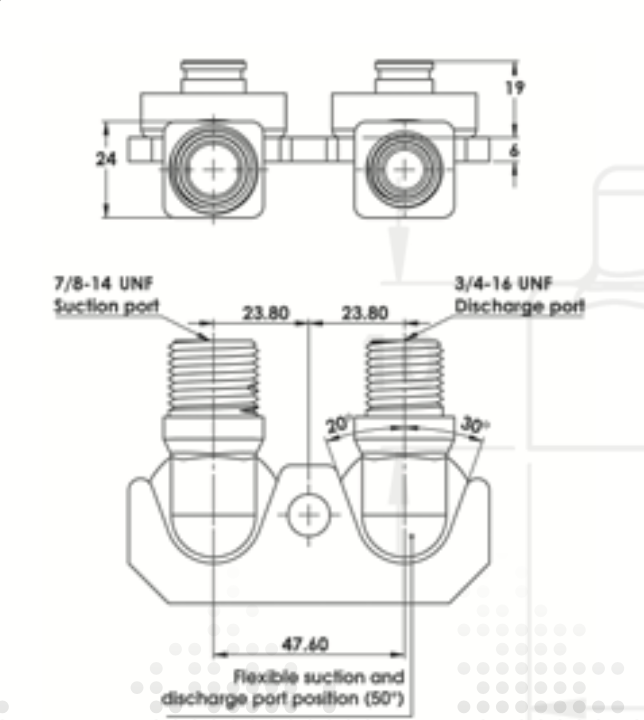

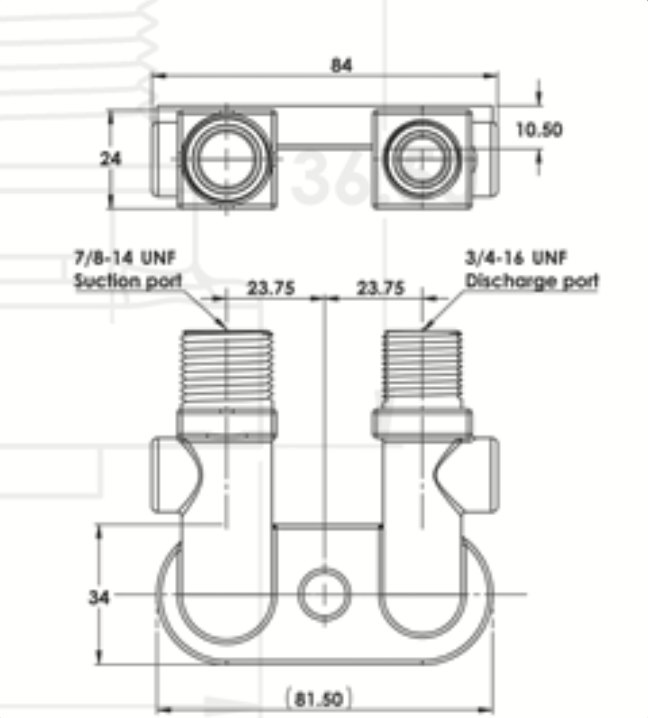

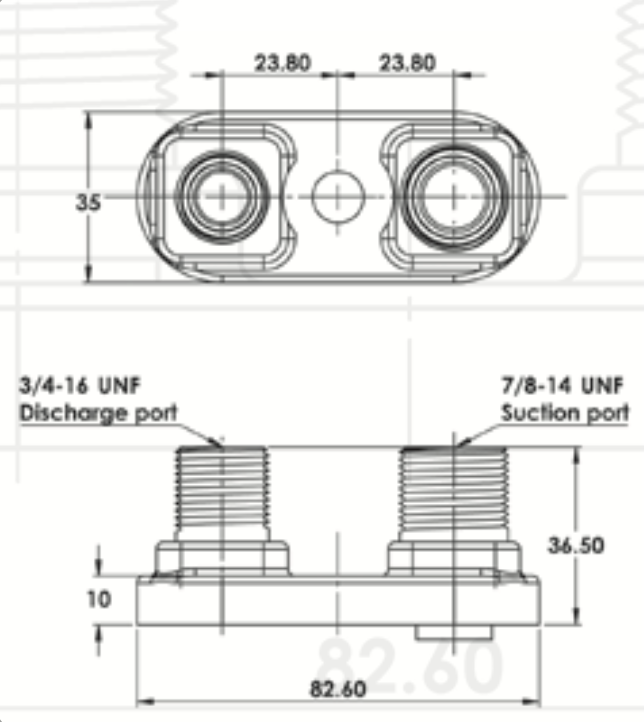

Hose ports

Porting for horizontal or vertical hose connections are standard, achieved by heavy duty blanking plates installed on outlets that are not in use. A range of standard hose port manifolds is available.

Service valves

A low-side service valve is fitted to the rear cap, including a high-pressure relief valve.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000030) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

UM330 | UMF330

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 10-14 kW

- Displacement: 330 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The Multi Direct Mounting system on UM models provides a total of 12 mounting points (four on the left, right and bottom sides) enabling direct compatibility with TM31 and QP31 compressors. Each mounting point has an M10 x 1.5 mm threaded hole, providing excellent flexibility in engine mounting and bracket design.

Hose ports

Porting for horizontal or vertical hose connections are standard, achieved by heavy duty blanking plates installed on outlets that are not in use. A range of standard hose port manifolds is available.

Service valves

A low-side service valve is fitted to the rear cap, including a high-pressure relief valve.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000030) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

UN330

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 10-14 kW

- Displacement: 330 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The Multi Direct Mounting system on UN models provides a total of eight mounting points (four on both the left and right sides), enabling direct compatibility with Denso 10P30B compressors. Mounting points on each side of the compressor are 94 mm and 81 mm apart.

Hose ports

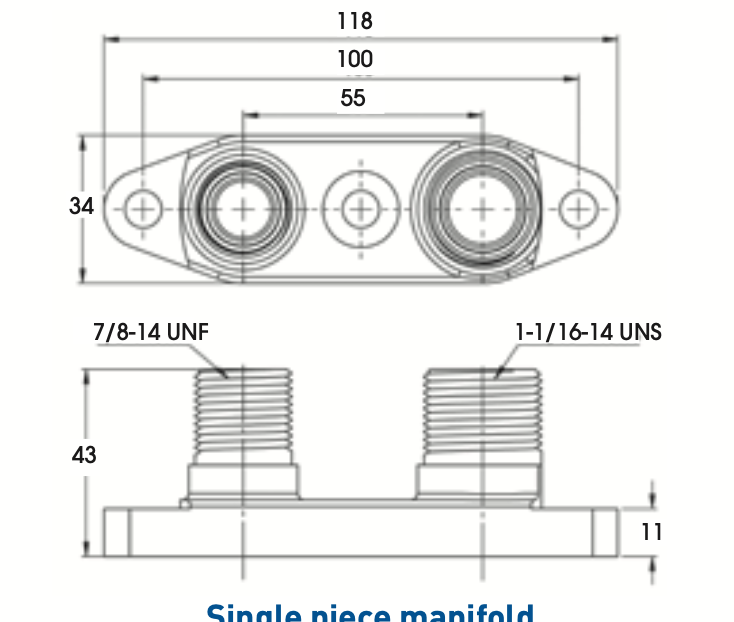

A single piece manifold is available.

Service valves

A low-side service valve is fitted to the top.

Oil return and other ports

An oil return port is not fitted.

UNX330

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 10-14 kW

- Displacement: 330 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat and operational fatigue

- Genuine NSK bearings throughout

Mounting

The direct mounting system (bolt-through) on the UNX provides a total of eight mounting points (four on both the left and right sides), enabling direct compatibility with Denso 10P30C compressors. Mounting points on each side of the compressor are 104 mm and 169 mm apart.

Hose ports

A single-piece manifold is available. Please see Clutch and hose port options on page 12.

Service valves

A low-side service valve is fitted to the top.

Oil return and other ports

An oil return port is not fitted.

UX380 | UXF380

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 12-16 kW and can be fitted into the same position as a Sanden UX330 or UXF330

- Displacement: 380 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat

Mounting

Suited to all mounting brackets made for direct mount (boltthrough) compressors with bolt holes 104 mm apart, including four M10 x 1.5 mm threaded holes top and bottom 75 mm apart.

Hose ports

Porting for horizontal or vertical hose connections are standard, achieved by heavy duty blanking plates installed on outlets that are not in use. A range of standard hose port manifolds is available.

Service valves

A low-side service valve is fitted to the rear cap, including a high-pressure relief valve.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000030) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

UM380 | UMF380

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 12-16 kW and can be fitted into the same position as a Sanden UM330 or UMF330

- Displacement: 380 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat

Mounting

The Multi Direct Mounting system on UM models provides a total of 12 mounting points (four on the left, right and bottom sides) enabling direct compatibility with TM31 and QP31 compressors. Each mounting point has an M10 x 1.5 mm threaded hole, providing excellent flexibility in engine mounting and bracket design.

Hose ports

Porting for horizontal or vertical hose connections are standard, achieved by heavy duty blanking plates installed on outlets that are not in use. A range of standard hose port manifolds is available.

Service valves

A low-side service valve is fitted to the rear cap, including a high-pressure relief valve. Oil return An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000030) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

UN380

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 12-16 kW

- Displacement: 380 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat

Mounting

The Multi Direct Mounting system on UN models provides a total of eight mounting points (four on both the left and right sides), enabling direct compatibility with Denso 10P30B compressors. Mounting points on each side of the compressor are 94 mm and 81 mm apart.

Hose ports

Both ports are fitted with a shut-off manifold assembly with back seating capability via stem valves.

Service valves

Low- and high-side service valves are fitted to the rear cap.

Oil return and other ports

An oil return port is not fitted.

UNX380

Features

- Sanden 10-cylinder swashplate

- Suitable for larger commercial applications with a system capacity requirement of 12-16 kW

- Displacement: 380 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation with excellent performance through all rev ranges

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Lip seal with high tolerance to heat

Mounting

The direct mounting system (bolt-through) on the UNX provides a total of eight mounting points (four on both the left and right sides), enabling direct compatibility with Denso 10P30C compressors. Mounting points on each side of the compressor are 104 mm and 169 mm apart.

Hose ports

A single-piece manifold is available.

Service valves

A low-side service valve is fitted to the top.

Oil return and other ports

An oil return port is not fitted.

UWX Series Compressors

The UWX compressors come in 508 cc (440 series), 607 cc (550 series) and 675 cc (660 series) capacities. Each weighs just 25.4 kg, with impressively compact dimensions of 324 mm (l) x 188 mm (w) x 303 mm (h). Specific models are available for R134a, R404a and R452a refrigerants. They can be supplied pre-charged with polyalkaline glycol (PAG) or polyol ester (POE) oil.

The compressors have a remarkably smooth and quiet operation with the lowest vibration level from any compressors of this size in the market today. With the current demands of modern transport, these compressors allow system designers to meet the most stringent environmental and efficiency requirements. The UWXF model compressors have been upgraded internally to better suit R404a and R452a low-temperature refrigerants.

Features include higher-gauge reed valves, a further refined and polished swashplate and RL32 polyol ester (POE) oil.

- UWX | UWXF 440

- UWX | UWXF 550

- UWX | UWXF 660

UWX | UWXF 440

Features

- Sanden 14-cylinder swashplate

- Suitable for refrigeration and air-conditioning applications with a system capacity requirement of 16-24 kW

- Displacement: 508 cc/rev

- Maximum continuous: 4500 rpm

- Smooth and quiet operation

- High in capacity (508 cc), low in weight (25.4 kg) with compact dimensions of 324 mm x 188 mm x 303 mm

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal)

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Sanden Multi Direct Mounting (MDM)

- Refrigerants: R134a, R404a, R452a

- Pre-charged with PAG or POE oil

- Genuine NSK bearings throughout

Mounting

The Multi Direct Mounting system provides a total of 12 mounting points (four on the left, right and bottom sides). Each mounting point has an M12 x 1.75 mm threaded hole, providing excellent flexibility in engine mounting and bracket design.

Hose ports

The suction port is located on top of the compressor and the discharge port can be taken from either the left or right side. Both ports are fitted with a shut-off manifold assembly with back seating capability via stem valves.

Service valves

Low- and high-side service valves are fitted on the shut-off manifolds, and on the rear cap of the compressor.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000050) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking

UWX | UWXF 550

Features

- Sanden 14-cylinder swashplate

- Suitable for refrigeration and air-conditioning applications with a system capacity requirement of 18-28 kW

- Displacement: 607 cc/rev

- Maximum continuous: 4,500 rpm

- Smooth and quiet operation

- High in capacity (607 cc), low in weight (25.4 kg) with compact dimensions of 324 mm x 188 mm x 303 mm

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Sanden Multi Direct Mounting (MDM)

- Refrigerants: R134a, R404a, R452a

- Pre-charged with PAG or POE oil

- Genuine NSK bearings throughout

Mounting

The Multi Direct Mounting system provides a total of 12 mounting points (four on the left, right and bottom sides). Each mounting point has an M12 x 1.75 mm threaded hole, providing excellent flexibility in engine mounting and bracket design.

Hose ports

The suction port is located on top of the compressor and the discharge port can be taken from either the left or right side. Both ports are fitted with a shut-off manifold assembly with back seating capability via stem valves.

Service valves

Low- and high-side service valves are fitted on the shut-off manifolds, and on the rear cap of the compressor.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000050) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

UWX | UWXF 660

Features

- Sanden 14-cylinder swashplate

- Suitable for refrigeration and air-conditioning applications with a system capacity requirement of 20-32 kW

- Displacement: 675 cc/rev

- Maximum continuous: 4,500 rpm

- Smooth and quiet operation

- High in capacity (675cc), low in weight (25.4 kg) with compact dimensions of 324 mm x 188 mm x 303 mm

- Clockwise and counterclockwise rotation with no change in volumetric efficiency

- Heavy duty impressed steel gasket and HNBR Japanese high-temperature O-ring (two-point seal

- Forged steel cylinder housing

- Drop-forged 5050 aluminium pistons with synthetic PTFE heat-treated rings

- Sanden Multi Direct Mounting (MDM)

- Refrigerants: R134a, R404a, R452a

- Pre-charged with PAG or POE oil

- Genuine NSK bearings throughout

Mounting

The Multi Direct Mounting system provides a total of 12 mounting points (four on the left, right and bottom sides). Each mounting point has an M12 x 1.75 mm threaded hole, providing excellent flexibility in engine mounting and bracket design.

Hose ports

The suction port is located on top of the compressor and the discharge port can be taken from either the left or right side. Both ports are fitted with a shut-off manifold assembly with back seating capability via stem valves.

Service valves

Low- and high-side service valves are fitted on the shut-off manifolds, and on the rear cap of the compressor.

Oil return

An oil return fitting – 7/16-20 UNF male flare (Part No. 42203- 000160) – is fitted on top of the compressor. It has a unique flow design suited to the Sanden oil separator (Part No. OS000050) and is interchangeable with the low-side service valve.

Other ports and fittings

Consistent M12 x 1.0 mm access port size. Easy interchange of blanking plugs, service valves, oil return and pressure switch fittings.

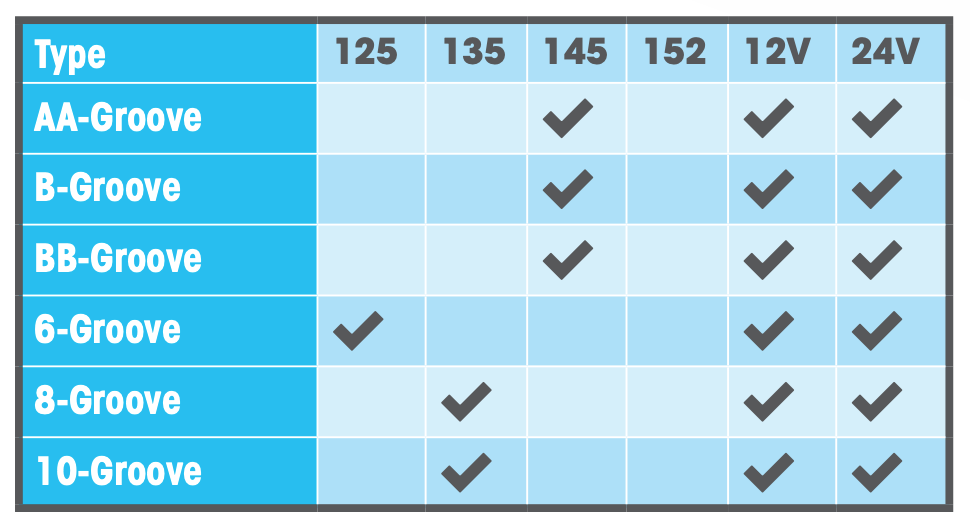

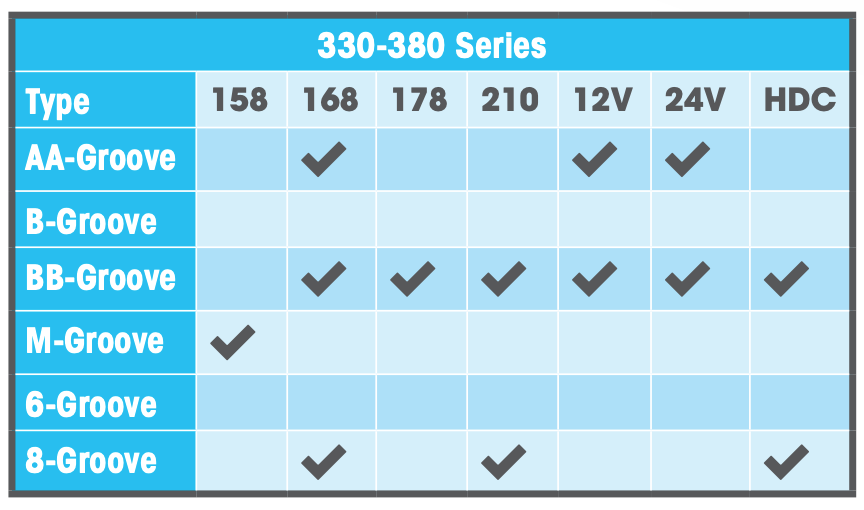

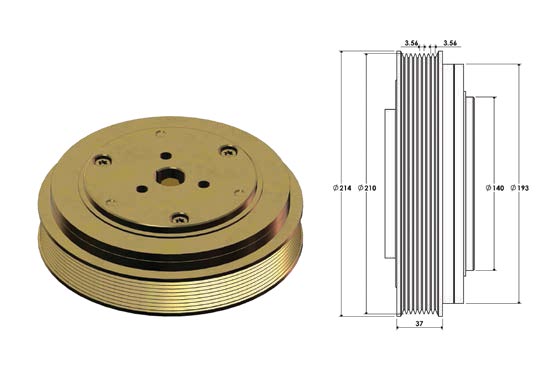

Clutch & Hose Port Options

- 200 Series

- 330-380 Series

- UWX Series

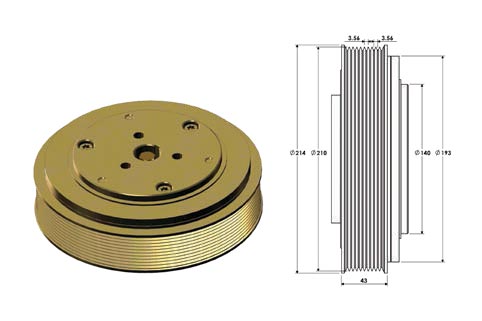

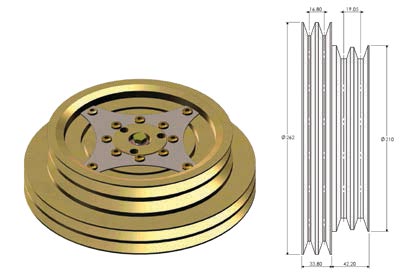

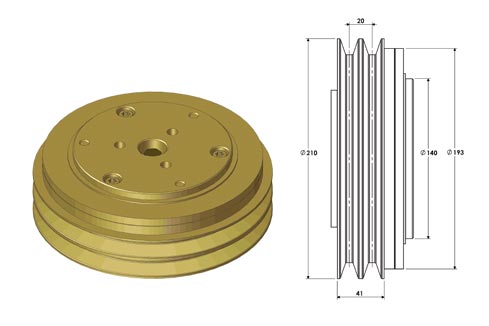

Clutches available for 300 Series Compressors

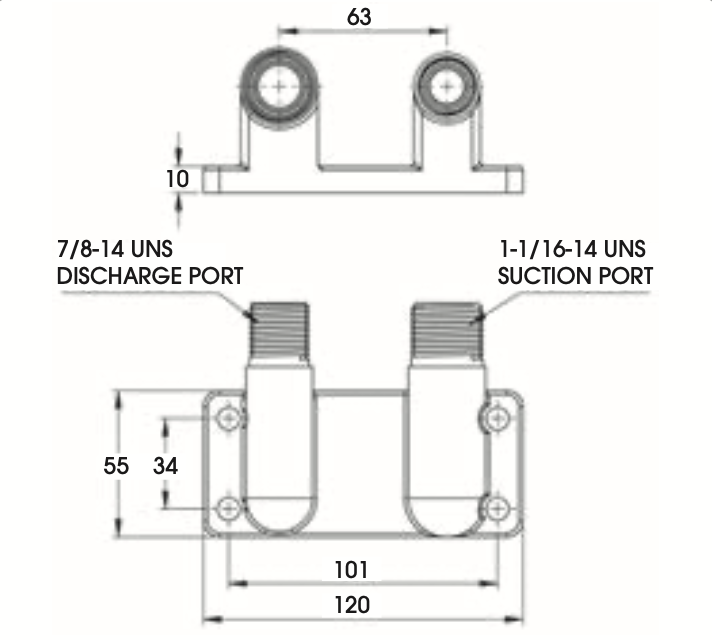

Single piece hose port manifold available for UN330, UNX330, UN380 and UNX380

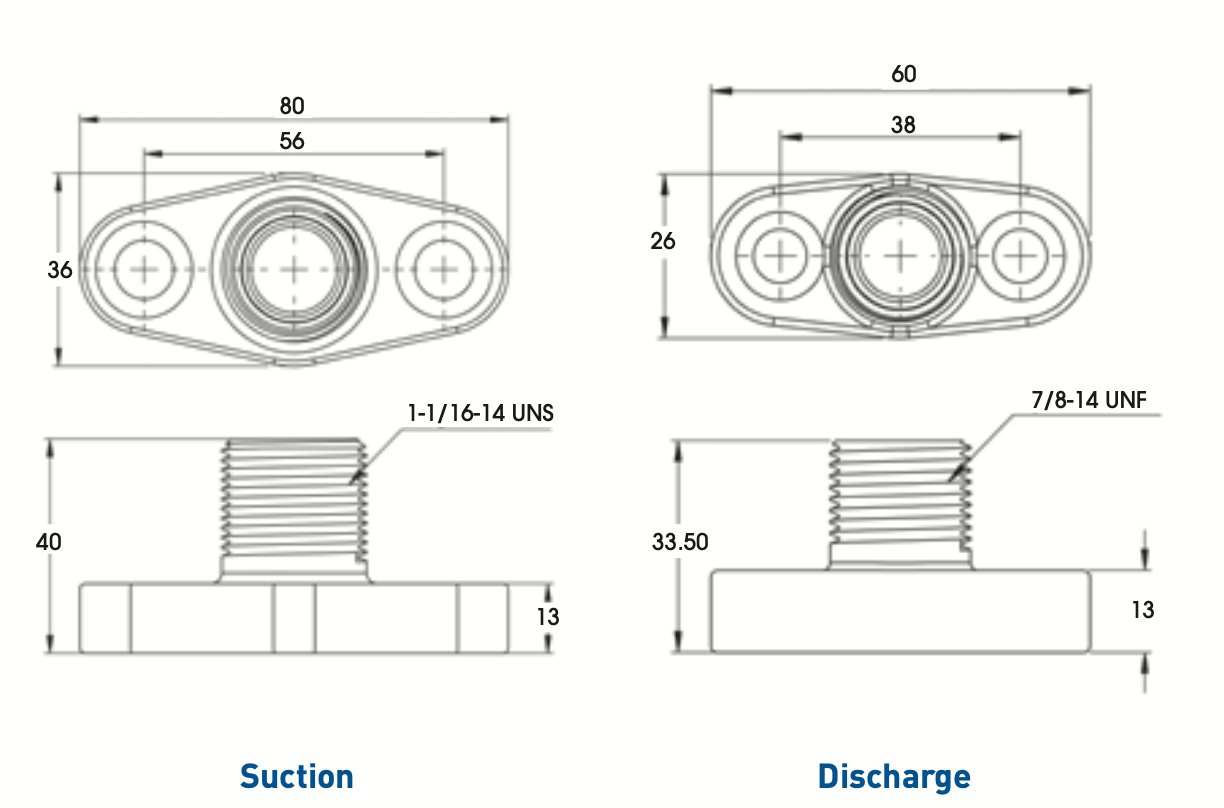

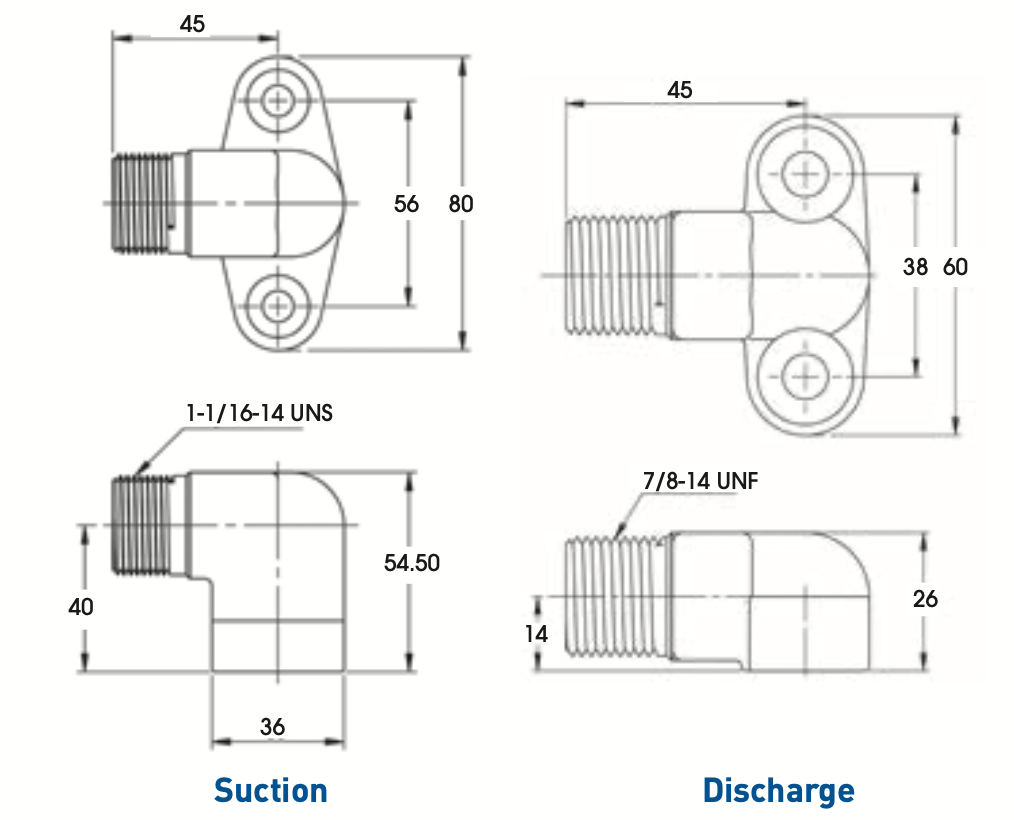

Hose port manifolds available for UM330, UX330, UM380 and UX380

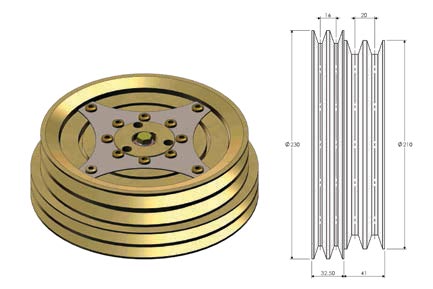

210-8PG-HD

230AA-210BB-HD

210-10PG-HD

262AA-210BB-HD

210-BB-HD

© 2025 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.