Southern Sales & Services supply Kendrion LINNIG electromagnetic large clutch applications for bus and coach climate control compressors.

This is the connecting element for belt driven power transmission between the crankshaft and the compressor, the air-conditioning system is switched on and off as required via the clutch.

LINNIG compressor driven clutches are used by the Market Leaders of the Bus and Coach industry weather for NEW installations or for after sale replacements.

If you have a requirement for a specific compressor driven clutch type, or you would like us to help you select a clutch from Linnig’s vast range for a new installation, then please do hesitate to contact us by phone or by using the quick contact form at the bottom of the page.

Along with the air-conditioning clutch compressor drives, Southern Sales & Services offer a variety of additional accessories for repair and servicing. A service exchange clutch rebuild program is available if you would like us to repair your worn out clutch.

LINNIG Drive Clutches

LINNIG Drive clutch – LA16

Compressor applications:

- GEA Bock FK40 / FK50

- Bitzer 4UFC – PFC / 6UFC – PFC

- Carrier Sutrak CS400 – 647

LINNIG Drive clutch – LA17

Compressor applications:

- Carrier 05K – 05G

LINNIG Drive clutch – LA18

Compressor applications:

- GEA Bock FK4

- Thermoking X426 / X430 / S391 / S616

LINNIG Drive clutch – LA30

Compressor applications:

- GEA Bock FK30

LINNIG Drive Clutch Accessories

- Clutch coils

- Clutch coil power cables

- Clutch bearing repair kits

- Clutch locking bolts

LINNIG Fan Clutches

Cooling – on demand and as needed – is achieved through precise and immediate switching of the fan by temperature sensors in the cooling circuits. Rapid temperature increases are tackled by immediate action of the fan. The drives are highly efficient. Fan capacities can be adapted in accordance with increasing cooling requirements.

LINNIG Fan Clutch – 1 Speed

The 1-speed is V-belt driven by the engine crankshaft pulley. When the electromagnetic fan clutch is not activated, the fan rotates with a speed of approx. 100 RPM. When activated, the fan blade runs synchronous to the drive speed.

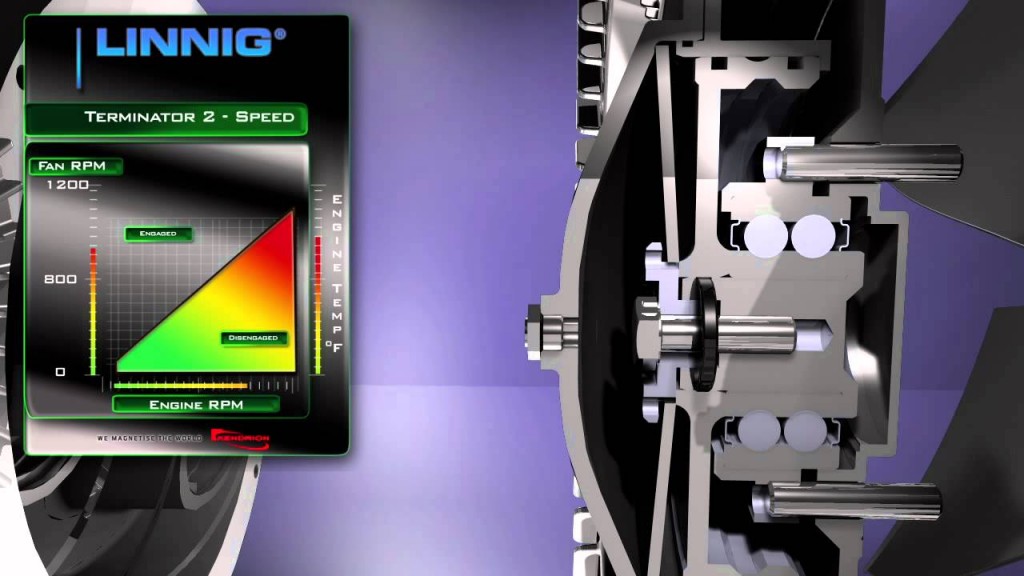

LINNIG Fan Clutch – 2 Speed

This electromagnetic fan clutch comprises two systems:

- Depending on fan size, the fan blade rotates – contact-free and non-wearing – at approx. 1,200 RPM, driven by a permanent magnet system.

- When required, the fan blade is switched by the electromagnetic clutch and rotates synchronous to the drive speed. The electro-magnetic fan clutch is activated by temperature sensors in the cooling circuit.

LINNIG Fan Clutch – 3 Speed

The 3-speed electromagnetic fan clutch is controlled by an electronic control unit or the engine EDC via temperature sensors. When the clutch is not activated, the fan rotates with up to 100 RPM. Approx. 1200 RPM, depending on the fan size, are achieved in the 2-speed stage via the permanent magnet system. In the 3-speed stage, the fan blade rotates synchronous to the drive speed.

LINNIG Angular Fan Clutches

LINNIG electromagnetic fan clutches are adapted according to the special applicational purpose. Depending on the application, fan clutches are available with angle gear, prop shaft and tensioning pulley in a single system unit and are used, as an example, for side-mounted radiators mounted in the direction of travel.

LINNIG Angular Fan Clutch – LLW 100

This drive unit consists of a 3-speed LINNIG electromagnetic fan clutch and an angle gear. The unit has a very compact design. Special gear ratios enable fan speeds to be adapted to the application.

LINNIG Angular Fan Clutch – LLW 200

LINNIG transmission technology for fan drives in coaches and buses has been tried and tested for many years. This further development for the EURO 6 engine generation offers the following advantages:

- High power/load ratio

- Total weight 10 kg

- Transferable torque 200 Nm

- Output speed up to 3000 rpm

- Noise-optimized. Clearly below the required industrial limit values

- Oil-change interval 180.000 km

- The innovative, integrated ventilation increases the service life of the shaft seals

- Temperature-resistant to 110°C

- Recyclable (to 100%)

- Reconditionable as exchange part

- Easy final assembly on state-of-the-art assembly line with 100% functional check

LINNIG Angular Fan Clutch – LLW 203

LINNIG transmission technology for fan drives in coaches and buses has been tried and tested for many years. This new development offers the following advantages:

- High power/load ratio

- Transferable torque 200 – 250 Nm

- Output speed up to 3000 rpm

- Noise-optimized

- Oil-change interval 180.000 km

- Temperature-resistant to 110°C

- High corrosion protection (500 h)

- Recyclable to 100%

- Final assembly on state-of-the-art assembly line with 100% functional check

The layout of the clutch in front of the angle transmission offers additional advantages:

- Service life is increased due to less load on the transmission components

- Further noise reduction

These advantages ensure less downtime and thus higher economic efficiency.

© 2025 Southern Sales and Services Ltd. All rights reserved.

Website made with by Thrive Digital.